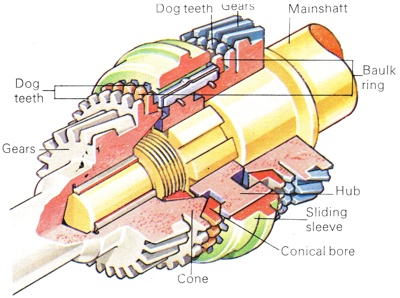

The widely used baulk ring synchromesh has toothed rings between the gears and the main synchromesh assembly. These have conical bores that mate with the cones on the sides of the gears. Between the hub and the sliding sleeve are three fingers, which protrude from the sleeve and locate in the baulk rings.

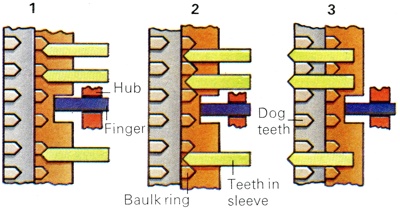

The teeth cut in the sleeve butt against those on the baulk ring (left), pressing the cones tofether and baulking the sleeve. The speeds synchronize (centre) and the sleeve's bevelled teeth rotate the ring slightly, allowing the sleeve to move on. Finally, the sleeve moves to engage the dog teeth on the side of the gear.

|

Baulk Ring Synchromesh

The baulk ring synchromesh system is only one of several ways of obtaining "unbeatable" synchromesh, though it is among the most widely used. It has been employed, with minor variations, on cars manufactured by Ford, Vauxhall (GM) and British Leyland. Its name derives from the fact that it has rings that "baulk" or refuse to allow the dog clutch to engage until the speeds of the dog clutch and the relevant gear wheel are synchronized. Like most synchromesh systems, the baulk ring design is double-ended.

This means that each end is equipped with an engagement device. Consequently, if the assembly slides down the mainshaft in one direction it will engage a gear, if it then slides in the other it will free itself from that gear and engage another. The gears employed with this type of synchromesh do not differ significantly from the example described above. Integral with the side of each gear is a hollow cone, around which is a set of teeth and these form one half of a dog clutch.

Rigidly mounted on the mainshaft is the hub of the synchromesh assembly and its outer edge is splined. These splines carry a sliding sleeve, the interior of which also has splines. These will engage the dog teeth on the side of the gear. The sleeve also has a pair of ribs which form a slot for the gear selector fork. Between each end of the sleeve and the adjacent gear is one of the baulk rings. These rings have conical bores that match the cones on the gears and the rings are therefore carried on the cones. The rings also have teeth which are similar to those on the sleeve and the dog clutch members.

The fixed hub on the mainshaft has three deep slots, each of which carries a loosely-fitting finger. Each end of these fingers locates in a slot in the baulk rings and circlip-type springs within the hub press a rib on each of these fingers into a groove in the sleeve above. Therefore, when the hub and sleeve turn (with the mainshaft) they will carry the fingers with them. As the fingers are, in turn, located in the baulk rings these will turn also. The baulk rings can, however, turn through a few degrees independently of the hub, due to the slight clearance between the fingers and their locating grooves.

The system in operation is best described by reference to a particular gear change, in this case from third to top in a four-speed gearbox. This means locking the mainshaft to the gearbox input gear. The movement of the gear lever into neutral disengages the sleeve from the third gear dog clutch on the mainshaft. Further travel towards the fourth gear position causes the fingers to press the fourth gear baulk ring hard against the cone on the side of the gear itself.

Now, the friction between the cones tries to slow down the gear and speed up the baulk ring and consequently throws the fingers to one side of their grooves in the baulk ring. This movement shifts the teeth on the baulk ring out of line with the splines on the sleeve. Therefore, the pressure on the gear lever forces the sleeve's splines hard against the baulk ring's teeth, with two results. First, it prevents further movement on the part of the sleeve and the sleeve cannot continue its travel and engage the teeth on the side of the gear, so it has, in effect, been "baulked". Second, the force of the sleeve on the baulk ring brings the coned portion into firmer engagement with the gear's cone and speeds up synchronization.

When the speeds of the gear and the baulk ring have been synchronized the friction between them falls to zero. There is a shallow V-shape to the tips of both the baulk ring teeth and the splines on the sleeve and these, coupled with the driver's force on the gear lever, produce a wedging action that rotates the baulk ring slightly. This brings the splines into line with the gaps between the baulk ring teeth, so the sleeve is able to move on and engage the baulk ring before sliding fully home to mesh with the dog clutch teeth.