Wolseley Fifteen 15 h.p.

Reviewed by Unique Cars and Parts

Our Rating: 5

Before the War

By 1913 Wolseley was Britain's largest car manufacturer selling 3,000 cars. The company was renamed Wolseley Motors Limited in 1914. It also began operations in Montreal and Toronto as Wolseley Motors Limited. This became British and American Motors after the First World War.

Entering wartime as Britain's largest car manufacturer Wolseley initially contracted to provide cars for staff officers and ambulances. Government soon indicated their plant might be better used for supplies more urgently needed. Postwar the chairman, Sir Vincent Caillard, was able to report Wolseley had provided (quantities are approximate): 3,600 motorcars and lorries including the equivalent in spare parts, 4,900 aeronautical engines including the equivalent in spare parts, 760 aeroplanes, 600 sets aeroplane spare wings and tailplanes, 6,000 airscrews of various types, Director firing gear for 27 battleships, 56 cruisers and 160 flotilla leaders and destroyers, 1,200 naval gun mountings and sights, 10 transmission mechanisms for rigid airships, 2,650,000 18-pounder shells and 300,000 Stokes's bombs

Scottish Horse Mounted Brigade's Field Ambulance developed an operating car, designed by Colonel H. Wade in 1914, which enclosed an operating table, sterilisers, full kit of instruments and surgical equipment, wire netting, rope, axes and electric lighting in a Wolseley car chassis. This operating car was employed during the Gallipoli Campaign at Suvla, in the Libyan Desert (during the Senussi Campaign) and at Kantara in Egypt, before being attached to the Desert Mounted Corps Operating Unit in 1917. Subsequently taking part in the Southern Palestine Offensive, which culminated in the Capture of Jerusalem.

Thomas Vickers died in 1915 and Albert Vickers in 1919 both then in their eighties. During the war Wolseley's manufacturing capacity rapidly developed. Postwar the Vickers Directors decided to borrow and further expand Wolseley's works and to consolidate their motor-car interests in one company. Wolseley accordingly purchased from within the Vickers group: Electric and Ordnance Accessories Company Limited, the Motor-Car (Stellite Car) Ordnance Department and the Timken Bearing Department and announced Wolseley's future car programme would be:

- 10 hp four-cylinder two or three-seater touring car based on the Wolseley designed Stellite car

- 15 hp four-cylinder four-seater touring car

- 20 hp six-cylinder chassis to be fitted with a variety of the best types of carriage-work

Examples of all these models were exhibited at the Olympia Show in November 1919.

Beyond The Trenches Emerged A Wolseley

The Wolseley 15 h.p. was an example of technological advancement learned during war time manufacture of aeroplane engines. Alloy steel and light weight chassis, accelerated horse power of more than 20 percent on the average Wolseley without increasing the engine size. The most beneficial feature of the then new design was the power output, which only marginally increased fuel consumption and the characteristic smooth running of Wolseley was maintained.

The post-war 15 h.p. was a radical departure from traditional development manufactured by the company. Pressed steel channel section side members were used, tapering towards the front end and carried over to the rear axle. Three tubular cross members; two of pressed steel were fitted. The usual dump irons were not used in the car because of the spring system. Another tube was secured in brackets bolted to the frame to serve as a support for the front end of the gearbox.

The rear end was supported on the foremost pressed steel cross member. The rear pressed steel cross member carried the spherical end of the torque tube, and also the brake compensating shafts. At the extreme end of the chassis, there was another cross member of steel tube on which the petrol tank was slung in conjunction with two brackets bolted to the frame. The honeycomb radiator was bolted on with trunnion brackets to the top of the side members.

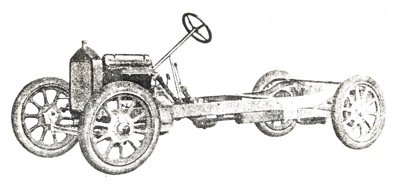

The Wolseley 15 h.p. Chassis

The Wolseley 15 h.p. Chassis

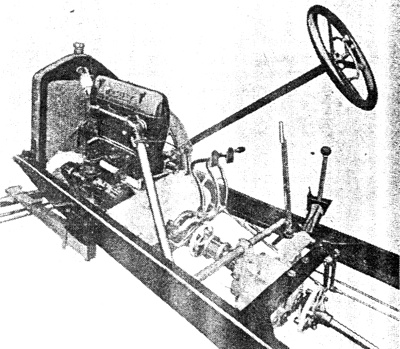

The Wolseley 15 h.p., front end of chassis, near side.

The Wolseley 15 h.p., front end of chassis, near side.

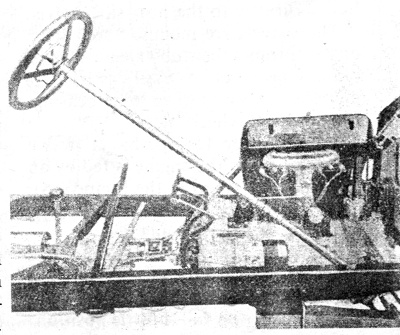

The Wolseley 15 h.p. front end of chassis, off side.

The Wolseley 15 h.p. front end of chassis, off side. |

The Wolseley 15 h.p. was powered by a four-cylinder engine, having a 3 inch bore by 5 inch stroke with a swept volume 2,614 cubic centimetres. The whole cam gear was lubricated efficiently. Excess oil, which in that era was prone to cause problems by carbonising valve stems etcetera, was alleviated by the oil being fed into various surfaces under marginal pressure, as the pipe used had an open end. Valve springs were accessible since the rockers were mounted on assemblies of four on each fulcrum pin; two on each side of the housing. Even in the worst situation, you only had to dismantle two rockers to replace a valve spring.

Errors in alignment were found to be non-existent, thus the spring drive was deleted and a steel shaft substituted. The shaft had a splined end at the top, with a master serration to allow timing difficulties impossible if the cylinder head had been removed. Die cast aluminium pistons with domed tops were used, each had three rings above the gudgeon pin. Stampings of 3 percent nickel steel of usual H section was used for connecting rods with the measurements of 10.25 inches between the centres. Direct white metalling was utilised for the big ends. The cap was provided with a dipper for lubrication.

A standard practice by Messrs. Wolseley in all car engines continued; die cast white metal bushes throughout the aluminium bearing caps were well registered into the crank case. Two silent chains were used for the accessory drives. A shorter one was used to drive an intermediary that was mounted on the centre line above the crank shaft. The longer chain ran from the near side of the engine, where it drove water pump, dynamo and distributor assembly.

The Wolseley 15 h.p. Clutch

The multi-plate clutch, typical of Wolseley cars from the era, consisted of thirty eight steel plates running in oil. Pedal action for the clutch was in the usual manner. Acting on a ball thrust, the pedal was carried on brackets bolted to a cast aluminium cover which enclosed the upper half of the fly-wheel. The pedals were adjustable to suit driver requirements, whether you had grown an inch or two over the years, or perhaps, decreased in height; the pedals were easily moved up or down, whichever the case may be. The clutch stop was made of steel pressing faced with fibre and was bolted on two brackets to the cover.

The Wolseley 15 h.p. Gearbox

A three speed reverse gearbox was standard equipment and cased in hardened steel. On the off-side of the gearbox a facing was provided and a gear selector assembly and change speed lever was one complete unit. This whole mechanism and gate was supported from this facing only to allow flexing in the chassis, if any, to not affect the gear change mechanism.

The Wolseley 15 h.p. Transmission and Gear Axle

From gearbox to forward end of the torque tube, the drive was through an open shaft with a Hardy flexible disc at the gearbox end and a sliding pot type joint enclosed in the spherical torque tube attachment, supported from pressed steel cross member. An under-type worm was employed for the final drive; ratio 4.8 to 1. Timken roller bearings carried the worm and a large external screw which acted on the steel housing of the rearmost bearing, providing for easy adjustment.

The Wolseley 15 h.p. Brakes

Internal expanding duplex brakes acted on the rear wheels. The shoes were faced with Ferodo and the brake drums were pressings of steel with fitted cast iron liners. The brake design was unique, for although two brakes were fitted in each wheel, single width drums were only used. Of course, the brakes still acted independently and the cams were at right angles to one another and either brake expanded the shoes diametrically as normal. The brake function was practical and enabled the surface wear of the shoes to be distributed evenly, which was not as a rule the system employed at this time.

The Wolseley 15 h.p. Steering Gear: Front Axle

The steering box was arranged with the plane of the worm at 90 degrees to normal. Instead of the usual fore and aft rod to the off-side swivel, the steering lever came below the box and projected forward, while the steering drop arm was linked directly to the near side swivel. The swivels were manufactured from nickel chrome; the stub axle and swivel pin were in one piece. Steel castings were mounted on two Timken roller bearings for the front wheel hubs.

The Wolseley 15 h.p. has a twelve gallon tank and the engine was fed by an Autovac tank fitted at the bonnet. An S.U. carburettor was standard but modifications were available. One such example was the Wolseley patented slow running tube, and an auxiliary jet that operated when the vehicle came into full throttle position. Its manufacturers claimed that the system produced remarkable fuel economy by one suction control jet and another controlled by the throttle working together in unison.

Under normal road conditions, the Wolseley was capable of 24 m.p.g. with a full crowd on board, without the well stocked picnic hamper that accompanied the family outing of the day. Sankey steel wheels, 815mm x 105mm were standard. The colonial model however, was fitted with 875mm x 105mm. Wheelhouse and track - 9' 10" and 4'4", while the weight of the chassis reached 16 cwt. Although intricate design was evident in this model Wolseley 15 h.p., some considered even that the complexities were unnecessary, but no-one could dispute that the vehicle was ahead of its time, in technological achievement and courageous for sight, regardless of her critics. The Wolseley 15 h.p. remains as an example of Messrs. Wolseley's part in the automotive history of Britain.