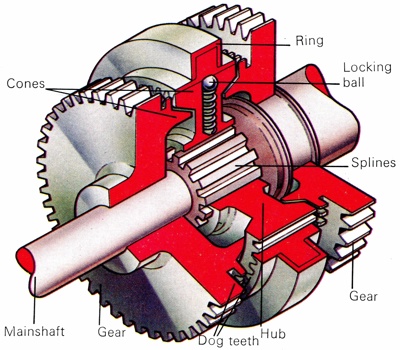

The gear pinions used in the oldest design of the synchromesh unit have a ring of dog teeth and a cone. The cones are matched by those on a jub splined to the mainshaft, while the second sets of teeth are formed by the internal splines of a ring carried on the hub. The ring is held in position by a spring-loaded ball.

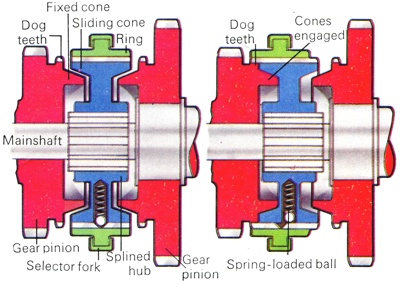

The same synchromesh, in neutral (left) and engaged (right). When the gear lever moves the assembly along the mainshaft the cones make contact and friction synchronizes their speed. The ring can then move further forward and the teeth on the gear and in the ring engage. The movement also depresses the locking ball.

|

Cone Synchromesh

The simplest form of synchromesh is now rarely used but it illustrates the principles on which many of the more sophisticated systems operate. The side of the gear to be engaged has two features. First, it has a hollow cone and second, the cone is surrounded by a ring of dog teeth. The cone and the teeth are the components that the synchromesh mechanism contacts when a gear change is made.

The synchromesh mechanism itself comprises two parts. It has a central hub that is located in narrow splines cut into the mainshaft of the gearbox which allows the hub to both turn with and slide along the mainshaft. The second part of the assembly is a ring, with teeth that match those on the side of the gear wheel. The ring is, in turn, splined to the hub but is restrained from sliding along it by a series of spring-loaded balls that locate in recesses set into the ring.

The mechanism is quite straight-forward in operation. Most gear changes are made in what appears to be one smooth movement by the driver but they do, in fact, comprise two stages, moving the gear lever into neutral and then into the desired position in the gear lever "gate". The gear lever is connected to the collar of the synchromesh assembly, so when the lever is moved into neutral the whole assembly, comprising the hub and the collar, moves up the mainshaft. This brings the two cones, one on the gear wheel and one on the synchromesh hub, into contact and the cones turn together. The friction between the cones forces both the gear wheel and the synchromesh assembly to turn at the same speed.

When the driver moves the gear lever into the second stage he consequently puts greater pressure on the synchromesh assembly. The hub cannot travel further as it is already pressed hard against the gear wheel so the extra pressure forces the collar to slide along its splines, compressing the spring-loaded balls. This movement of the collar brings its teeth and those on the side of the gear wheel into contact and they therefore engage.

The gear wheel is then locked to the mainshaft through the collar and the splined hub and the gear changing process is completed. This type of synchromesh works well in theory but has proved to be less satisfactory in practice. It depends on the two cones achieving synchronization before the gear lever is moved into its second position but it does not guard against the effects of an impatient driver's gear change.

If the gear lever is moved early, the driver will "beat the synchromesh" and will force the dogs into contact before the speed of the components has been synchronized. If this happens all of the old faults will arise, such as the grating noises, inefficiency and heavy wear on the teeth of the dog clutches. The solution is to incorporate a component that will prevent the dogs from engaging until the cones are running at the same speed. There are, in fact, several types of synchromesh that feature such a device.