Based in Detroit, the Federal Motor Truck Company manufactured the aforementioned trucks of various size from 1910 to

1959. The company was founded as Bailey Motor Truck by Martin L. Pulcher, who would later found the Oakland Motor Car Company. The last Federal vehicle made for the US marketplace was made in

1959.

The History of Federal Trucks

By Rolland Jerry

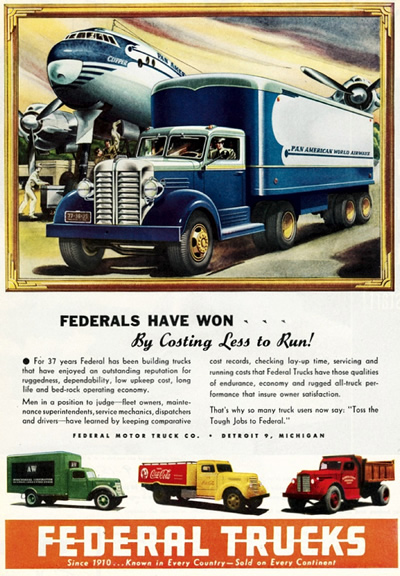

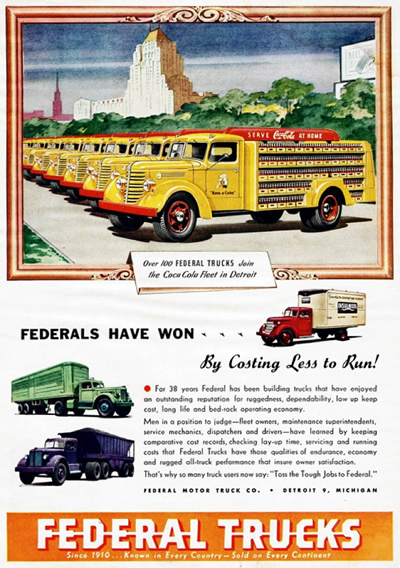

The Federal Motor Truck Company 's premise was a quality unit yet produced in sufficient volume for keen prices and of course allowing lots of scope for options and specialized specs. These units, the handiwork of an old-line Detroit independent, were well thought of and still are by oldsters in trucking and transport who can recall Federal's heydays and the popularity of the outfit's vehicles. Like the Studebaker and the Hudson perhaps in passenger cars, the Federal was a make that "dad", "Uncle George" or "Cousin Harry" once had, especially in families with a background in trucking, transport or cartage.

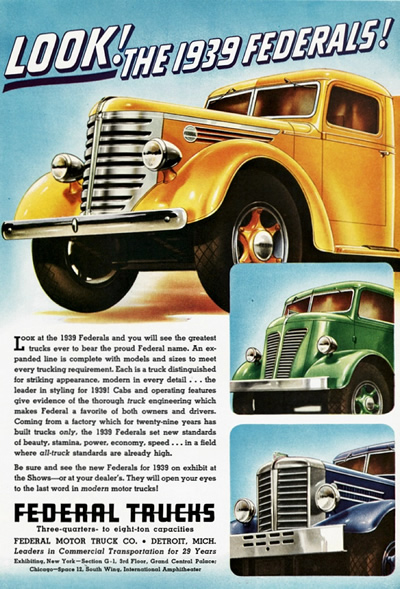

The company's trucks were thoroughly conventional, save perhaps for a few short-lived light duty jobs powered by sleeve valve engines in the 1920s. Federal made its mark with a proven formula, that is, straightforward and basic design free of radical, "advanced" and possibly unproven features. Federal was conservative and so were the firm's customers. This certainly wasn't the case with the company 's traditional and hottest rival, up-and-coming Diamond T and the early successes the outfit scored with its emphasis on swank passenger car styling, two bar bumpers and lots of chrome. The Federal may not have been a Plain Jane but there could be no denying that D-T was on the right track for (comparatively) jackpot sales.

That's what happened, too. For instance, Federal outsold Diamond-T in 1927 and 1928 (roughly 3.500 U.S. sales registrations vs. Diamond-T's 2.000 odd) but thereafter Diamond-T took the lead and never lost it. Federal's sales tumbled, dwindling to 1,300-2.000 registrations during the depression years, by which time Stewart and Brockway, two other independents, shaped up as rivals, though Stewart failed to maintain its competition for long. But Federal wasn't doing too badly for the depressed times. No one else besides Diamond-T was gaining ground and Federal was at least holding its own when others were in worse shape by far.

Federals were never more than a mix of stock and familiar components, essentially wares from Continental, Waukesha, Clark, Timken and Brown-Lipe, many in fact also shared with Diamond T and other assemblers producing similar trucks. But Federal did have more equity in its vehicle than many assemblers, since the firm had a large machine shop in the Detroit plant (appropriately enough on Federal Avenue) for the production of spring hangers, radius rods, shackle pins and chassis hardware generally. It was no small plant either with some half a million square feet and a workforce of 600 or 700, with the trucks assembled on a 600 foot line for volume output.

Then, too, Federal maintained a large bodybuilding facility for the output of standard and custom bodies. This wasn't unusual among small truck producers - in those days though Federal's was on a substantial scale. The idea, of course, was to realize the profit on the body as well as the chassis, also to produce an integrated vehicle without the intervention of an outside bodybuilder. Federal's bodywork followed proven and familiar practice, essentially hardwood framing ruggedly ironed and reinforced and clad with steel panelling. Federal had large and first-rate painting facilities with big production booths. And back when lacquer was a new and shiny development in the industry Federal had its own, "Fedlac", a big feature on the 1929s and specially compounded for a lasting, durable finish.

Federal Trucks Standard and Deluxe

Similarly, Federal produced its own cabs though some were purchased in the early years from several vendors. Curiously. Federal offered two cabs through the 1930s, the standard and the deluxe. Interestingly, the differences were considerably wider than simply deluxe equipment fitted to a standard cab for the deluxe version. Instead, two separate cabs were used, one with more curves and a higher standard of finish to distinguish it from the standard job. When truck manufacturers offered a "deluxe" cab in those days they meant it. And the tab was insignificant, say $100 for the standard unit and $50 more for the deluxe cab!

In passing, Federal always exhibited at the big New York Motor Show during the. 1920s and the 1930s, often with as many as eight units on display. The occasion was usually taken to introduce a new model or perhaps remind customers with an array of custom vans that the company also built high-class bodywork for its chassis. Federal's capacity to build bodies and cabs would be important later on as we'll see. As to models and units, the Federal line-up through the 1920s and the 1930s typically ranged from a 1-tonner at the "light" end to a hefty 7½-ton job at the other, with spiral bevel axles on the lighter units and worm-gear or double reduction choices for heavier jobs. Similarly 4- and 6-cylinder engines were offered through the 1930s, with fours available in light duty jobs at one extreme an in the heavy 7½ ton unit at the other.

1938 Federal Truck

1938 Federal Truck

1939 Federal Parcel Van 1939 Federal Parcel Van

1939 Federal Heavy Duty Truck

1939 Federal Heavy Duty Truck

1946 Federal Heavy Duty Truck

1948 Federal Heavy Duty Truck |

The Federal Big Six

Federal turned to an interesting engine in 1928 for the fast (40 mph) Federal Big Six. The choice was one of Continental's new ohv "K" series engines developed for heavy duty truck and coach service. Federal selected a 20R for the Big Six, a 318 cu in engine with an output of 84 hp at 2,200 in Federal's version, since Continental's stock 20R was rated at 87 hp at a "high' 2,400rpm.

This engine was the first of many K series Continentals to go under the hoods of Federals though of course the company had used other engines of the same make for many years. Later versions of the R series were offered right up to the end of Federal production, by which time they afforded outputs up to 200 hp.

Actually, the largest engines Federal used were supplied by Waukesha. For instance, the 7½ tonner - Model X8 and the company's heaviest job - was powered by 5x6-in 4-cylinder Waukesha in the mid 1920s (though with the option of a Continental R series engine <100 hp) and pneumatic tires by 1931. Much the same prevailed in 1939 with the introduction of a new range of heavy duty jobs.

With these, customers had the choice of a 501 cu in R series output of 139 hp and 385 ft lbs torque at 1,200 rpm, or a 517 cu in Waukesha offering 133 hp and 400 ft lbs torque at a low, low 700 rpm. Basically, the Continental R was a "high speed" engine for highway service while the Waukesha was a "lugger" with steam-like torque for slow-speed "pull".

Then, too, Hercules engines - many shared with Diamond T but without the latter's exclusive counterweight crankshafts, at least for a time - came into the Federal line in a big way from 1933 on, mostly for light and medium duty units. And before we leave the 1928 Big Six, the job was revised in 1930 with an upgraded 20R - now with twin ignition and an output of 90 hp.

A novelty was the built-in or integral 2-cylinder Westinghouse compressor for four wheel air braking, an improvement on the 1928 Big Six with its two-wheel brakes, which were mechanical aided by a Westinghouse vacuum booster. With better braking and more power, the Big Six's rating was increased to "4-5-tons" and a good deal more when used as a tractor where air brakes simplified trailer hookups.

Federal's Emergency Brake System

Speaking of brakes, heavier Federals of the 1920s and the 1930s embodied a curious "emergency" braking detail which could be used in conjunction with the more conventional service brake setup, which was mechanical initially, then hydraulic and of course also by air. Federal's "emergency" consisted of a large diameter cast iron drum (up to 4½ x 4½ ins) which was mounted on the nose of the axle pinion gear, reacting out to the wheels through the shafts.

The idea was to reduce braking strains on the driveline, particularly the U-joints, and to make braking as "direct" as possible in an approach short of putting the shoes inside the drums at the wheels. Actually, Nelson Brownyer, Golfredson's chief engineer in the 1920s, had used a somewhat similar arrangement earlier on Gotfredson trucks. But in this case the service braking was vested in a drum mounted on the axle's worm shaft while the "emergency" was linked to the shoes in the brake drums of the rear wheels.

Brownyer recalls that the Timken-Detroit Axle Company raised a hue and cry at the braking loads passed through the axle though the arrangement proved very satisfactory with the loads and low speeds of the day. The Gotfredson was built in Detroit, too, and perhaps Federal was influenced in its braking details by the effectiveness of the Gotfredson arrangement. In any case braking through the driveline - service and "emergency" - wasn't unusual in the early days though customarily the drum or'disc was mounted directly behind the transmission, in fact a popular spot for the "emergency" for decades.

Federal Trucks and the US Army

Federal enjoyed a long and a continuing association with the U.S. Army for the supply of military- and civilian-type vehicles though admittedly orders were few and far between after 1918. But this changed, and rapidly so in the mid-1930s with a succession of orders filled for the U.S. Army. The company's main contribution in World War 1 was the 3-ton "Aviation Heavy", according to "The Observer's Army Vehicle Directory to 1940", B.H. Vanderveen, Frederick Warne & Co. Ltd., London,

1974. The unit was a rationalized or standardized job similar in aims and concept to the more familiar Class B 5½ tonner.

The "Aviation Heavy" was built by several truck manufacturers, as was a lighter version, the 1½-ton "Aviation Light". Both were conceived as tenders and transport vehicles for the Signal Corps/Air Service. The company had orders for 1,000 of these units and it's reported that around 600 were shipped to France where they undertook a variety of duties apart from Air Service needs. In passing, the writer remembers seeing an "Aviation Light" in the late 1930s, winding up its long career as a "yard" hack for a sawmill operator in upper New York State.

The event springs to mind as my father was asked tq take the "Light" as a trade in the purchase of a small Cletrac crawler tractor. New trucks and tractors were difficult to sell in hard times and dealers were often faced with some incredible and unlikely "trades", though few more improbable than a well worn 191B "Aviation Light" still on solids and commanding a lot and/or scrap value of all of $15! The Lights'distinguishing features were the handsome disc wheels, an unusual detail in an era when the cast steel and wooden spoke variety dominated.

From 1934 onwards. Federal and other truck manufacturers benefited from a succession of large scale (for the times) orders placed by the U.S. Army for military vehicles. Thousands of units were involved - a mix of civilian and military types - and the big purchases served as a needed shot in the The U.S. Army's move arm for truck manufacturers faced with flagging depression era sales. The US Army's move wasn't triggered by a particular sense of preparedness or anticipation of the war - it was much too early for that - but rather by the fact that its World War 1 vehicles were not only obsolete but also worn out.

The military had made out for years using World War 1 surplus but the time had come for newer, lighter and more efficient vehicles. Actually, the Air Corps had come to the same conclusion in its own field a few years earlier when it rid itself of war surplus Cuttiss OX-5 and Liberty aircraft engines, then still numerous, by simply withdrawing them from service for replacement with new and more advanced engines. In passing, the Army and the Air Corps weren't much of a market for anyone In the 1920s and the early 1930s with the glut of 1918 equipment which both had to "use up" to save the taxpayer's dollar, a policy which allowed few new purchases apart from "experimental" vehicles and aircraft rarely acquired in more than ones and twos.

All that changed in 1934 and the truck world gained. At that, the big expenditures came as no surprise: manufacturers and component specialists had been working with the authorities for sometime in the development of new vehicles, all-wheel-drive power trains, axles and other components which could be assembled into a standardized range of military trucks. The scene - which laid much of the groundwork for the Vehicles used in World War 2 - was described as a "four-wheel-drive craze", with truck manufacturers and component suppliers in a frenzy to push through development. It was good for business, too.

Then as now, the government called for tenders to produce the new vehicles, issuing the specs to manufacturers for their bids. This is an interesting area, the procedures in "procurement". Contrary to popular opinion, not all military orders are "big money" or even profitable and sometimes manufacturers avoid them when times are good and ordinary civilian' vehicles return higher profits. Then the government formally "asks" reluctant manufacturers for their bids to assure the widest possible representation in purchasing, which is as it should be with federal expenditures.

Wartime production is something else again, of course, and quite a different matter. One can be reasonably sure there was little indecision or humming and hawing among manufacturers when the specs were prepared for bidding. After all, the civilian truck market had bottomed out with the times though some slight recovery was apparent by 1934. A nice military order meant a lot, particularly to the assemblers with plants ideally suited for the production of special jobs assembled from vendor components.

The Federal Q9

Federal Trucks got one of the largest contracts, an order for an impressive 400 Q9's and worth more than a million dollars. Now the Q9, a 2½-tonner, was the embodiment of all that the U.S. Army's Quartermaster Corps deemed worthy in a truck, not an unreasonable view with the military's participation in its specs and design. A 4x4, the Q9 employed Timken double reduction axles (with CV joints on the front one) and probably a Timken transfer case as well, with the lot linked to a 4-speed Brown-Lipe and a 6-cylinder Waukesha engine.

The job liad striking grade ability - up to 57% - and it sat on 9.00/20's. Fuel consumption, loaded, was 6½ mpg, with smooth road performance up to 34 mph and 18 mph "cross country". A feature of the 4-1/8 x 4½ in Waukesha was the lube setup - two oil pumps to maintain pressure no matter at what angle the vehicle was tipped or driven.

The Q9 was also intended to tow a field gun on occasion, the frame was in proportion - a 10 x ½ in heat-treated rail. This was a departure from Federal's civilian specs which did not include heat-treated frame rails. The Q9's snazzy side-mounts did more than boost the job's looks: if needed - and only temporarily - they could be bolted to the front wheels to improve traction and flotation. The Q9 was a tidy, compact powerhouse with plenty of urge.

Federal fitted the job with hydraulic brakes, an oversize radiator and one of its own cabs, supplying the unit complete with body and equipment to the Army. Several other manufacturers received orders for generally similar units but Federal got the lion's share for 2½-ton 4x4s. The company's sales of civilian trucks hadn't been very hot with the lousy economy, namely 1,962 registrations in 1934 and a so-so 2,190 in 1935 plus a couple of hundred more for export. Thus there would have been ample production capacity for the big Q9's, which Federal assembled on its regular line.

Unhappily, space doesn't permit a more detailed exploration of Federal's interesting pre-war military sales but in a nutshell the company did well, in fact an understatement when another big order was forthcoming in 1936. This called for 213 2½-ton civilian-type Federals (Model 15s adapted for military use) and a volume worth a quarter of a million dollars to the company. The civilian sales area was improving but fitful, up to 2,930 registrations in 1936 but then down again to 2,366 the following year - of course in addition to whatever worldwide (and weak) export markets were taking in new trucks. As an assessment, Federal stood 11th in U.S. truck sales in 1936 and 10th in Canada. The latter had been an excellent market for Federals and always good for 150-200 units annually during the 1920s and the early 1930s, though sales declined fast with the depression, diminishing to a alarming 20-odd in 1933 but rallying to around 50 units by the late 1930s.

Federal Trucks in Canada

Canada was a small-scale duplicate of the U.S. truck market which was in no better shape. Federal undertook a Canadian "assembly" operation in 1932 to offset new and higher duties on imported vehicles though this had no noticeable effect on sales apart from allowing the company to stay in the market. Federal was a textbook example of a breed that's almost disappeared from the truck world today, an "all line'" manufacturer. The company built a complete line of vehicles from '/<- and 1-ton to the heaviest units on the market. Only Ford and GMC/Chevrolet do so today with abdication of Inter- " national Harvester' from the light duty field and the Chry-sler Corporation from the .Cleftr um and heavy duty end of the truck world.

But it was different in the 1920s and the 1930s, even into the post-war years, when most manufacturers, particularly the independents, produced a full range of vehicles, many starting at 1-ton. The lower end of the truck market hadn't become quite so competitive and by and large the Big Three were still preoccupied with passenger car sales. Of course, they offered light trucks - '/-, 1- and l'/i-tonners in the 1920s and the 1930s - but without much specialization. Then, too, there was a world of difference, between, say, a l'/i-ton Ford AA and a comparable Federal, which cost twice as much but with heavy duty specs in proportion.

Federal's big bodyshop was a major benefit in this connection, essentially standardized and deluxe van bodies on 1- and 1½-tonners enabling sale of the unit as a complete vehicle. In passing, the company turned this facility to curious purposes in 1936, the production of Federal "Motohome" domestic trailers. The company got into this unlikely field only long enough to get out of it, though a few demonstrators were built. Federal dealers - many of ;whom also shared passenger car franchises - could sell the unit but the main intension was to market the Motohome (and its commercial variant, the Motomart) through a separate organization.

The automotive industry was gripped by a fleeting but intense trailer mania in the mid-1938 when new and novel "house" trailers were the star exhibits at motor shows. The Hayes Mfg. Co. (bodies for Keo, Graham) got into the field and so did several custom coach-builders for a brief interval when every automobile dealer felt he had to offer a "Kosy Koach" to round out his wares. The bubble had burst and disappeared by 1939 when what business there was in the field was left in the hands of trailer specialists, most of whom thrived during the war years producing "temporary housing" for war workers and military demands.

Federal Trucks in the 1950s

"Times were changing very fast in the 1950s and I suppose the company could see that the future for an independent truck manufacturer of our size was uncertain at best. Besides, mergers, takeovers and big expansion programs were much in the wind during the early postwar years." That's how Louis Seaver remembers the Federal Motor Truck Company, Detroit, and the setting which culminated in the company's first merger in 1952. It's a story not much different from the circumstances which urged Sterling, Diamond T, Autocar, Reo and Brockway into mergers and new affiliations of their own a few years later. Lou Seaver should know he joined Federal in 1944 and stayed for 10 years before moving on to Ford though still in his own field, heavy trucks.

He remembers when Federal's tidy but aging plant on Federal Avenue was all but bursting at the seams and every inch of floor space was needed for wartime military production. For instance, 1944 was Federal's best year ever with net sales of nearly $34 million and a whopping increase of 39% over 1943. But it wasn't to last as Seaver also remembers other intervals in the postwar era when flagging sales forced a 50% cut in the wartime workforce of 600 to 700 workers. Briefly, Federal was founded in 1910 by Detroit interests who retained control of the firm until the first of two mergers in 1952. That year the company was acquired by the Fawick Airflex Company, a Cleveland-based outfit behind the familiar Fawick air-operated clutch. The move saw the formation of a new corporate setup, the Federal Fawick Corporation of which Federal was a division.

Seaver remembers that Fawick had hopes of using Federal as a springboard into the truck world for the sale of its unique air clutches for automotive applications. In passing, the Fawick clutch employed (and of course still does) air pressure, not springs, for the expansion and the contraction of its friction surfaces, affording easy and positive engagement, typically for heavy construction equipment and industrial needs. Then, too, Federal's military business was attractive to Fawick and it was seen as an area that might be developed: the early 1950s were uncertain years and military purchases remained at high level, in fact a very different picture than the years following 1918 when government expenditures for new equipment vanished with the Armistice and "the war to end wars." Seaver adds many government departments and civilian agencies posed more demands for trucks: "Federals were widely used by many state highways departments while the Tennessee Valley Authority - "TVA" -bought many, too."

However, plans to fit Federal trucks with Fawick clutches fell through as did the production of these units for other ive applications. On the other hand some success was scored with the substantial sales of trucks to the US army and the Air Force. Increasingly Fawick personnel assumed direction at Federal, almost always the case with the merging partner and changes of ownership and company control. Lou Seaver remembers that Fawick worked very hard to develop its new Federal division "but I believe they found the truck business totally unlike their own and perhaps not what they'd anticipated when they went into the merger." As an aside, he recalls that sometimes so much emphasis was placed on military orders that the sales of civilian vehicles suffered.

"The business was simply unbelievable," Seaver relates, "as we rarely had less than three customers for the same truck." The rosy interval is quite apparent in Federal's production figures for 1947 - a whacking total of 10,114 units of which 6,020 represented American registrations. "We could count on Australia taking 200 to 250 trucks a year and Central America another 600 or 700 in the late 1940s," he says, "not to mention heavy demands from South Africa, the Scandinavian countries and Belgium and The Netherlands." The Middle East was a bright, not a troubled spot at. the time. "I remember a very large order we filled for 500 45M's which were shipped to Saudi Arabia." for civilian trucks to balance and even out your production schedules, keeping the line moving for efficient output." Overall it appears that Federal problems in this respect, swinging from civilian to military production.

In any event, Fawick disposed of its Federal interests to a new owner in 1954, Napco Industries Inc., Minneapolis. Napco was, and still is, a major name in the component field with its axles, transfer cases and other units essential in four-wheel drive vehicles. Seaver says he has no knowledge of the transaction but he believes Napco was perhaps interested in a revival of Federal's once active export business. "Federals were well received throughout the world and export sales amounted to some 40% or so of our production in good years," he says. The early postwar years and the late 1940s saw the export area absorbing as many new Federals. Spain was another good market where the company's distributor, Barreiros, produced his own diesel engines, a number of which were used in Federals, before the operation was taken over by Chrysler of Spain.

But it wasn't to last. Export markets shrunk or disappeared by the 1950s with changes forced by tough currency controls and increasing demands in many countries for higher local content. "We lost some markets completely through currency controls," Seaver reflects, "and in other cases we were restricted by quotas which severely curtailed our sales." Federal responded as best it could though there were limits: the company had always shipped some units in "knocked down" form for local assembly while others were supplied with flat face cowls to accommodate locally-built cabs and bodywork.

Conceivably the picture might have been different had American component suppliers, typically Clark, Rockwell and Eaton to name a few, operated overseas plants as they do. now for the local supply of, say, axles and transmissions to American truck manufacturers selling the same markets. For example, American trucks have always been popular in Australia, so much so that several of main component suppliers now have Australian plants for the production of axles and transmission to increase the local content of American vehicles manufactured or assembled for this important market. Much the same prevails in greater or less degree in Europe and Great Britain but unhappily for Federal this wasn't the case in the 1950s.

Then, too, other problems were developing for Federal as Seaver notes: "One was the increasingly heavy competition we faced from the Big Three - Ford, Chrysler and GMC/Chevrolet - in their collective bid for a wider portion of the truck market." He recalls that Federal felt the competition in two ways, one, the tendency of the Big Three to move "up market" with larger and heavier models than they had been building, and, two, by the sheer weight of their dealer forces. "We had around 600 dealers at the time but they simply couldn't cover the market as completely as the Big Three with their dealerships on every street corner." Seaver reckons Federal matched the new competition with vehicles which offered excellent value "but there was no way we could reach or attract as many customers as they did." He remembers that the picture became very competitive, also one marked by heavy discounting which narrowed price and profit margins.

The Federal Style Liner

Actually, Federal had anticipated shifts in the postwar truck market somewhat earlier, deciding to leave the light duty area with the resumption of civilian production in 1945. Federal had produced these lighter jobs before the war, including a shortlived door-to-door milk delivery van inspired by the Divco, but these units were dropped with the postwar concentration on medium and heavy duty models, basically jobs with gvw's from 13,000 to 40,000 lbs. Federal reacted to changes in the truck marketplace with a new line of trucks in 1950, the Style liner series in gvw's from 17,000 to 24,000 lbs and gcw's to 40,000 and later to 57,000 lbs. Style Liners, designated the 1500 to 3000 series, replaced a number of units in the company's M series, an earlier range of vehicles which had been announced in 1937.

In the main Style Liners embraced the same ratings as Ford, Chevrolet and Dodge but with higher gvw's at the top of the line. The new unit was high styled and competitively priced. Seaver remembers it was well received at the New York Motor Show that year when Federal booked 600 orders for Style Liners. The new trucks rounded out what Federal had to sell, since company retained its heavier M series units, also initially a few of the smaller jobs in the same series with gvw's from 12,000 to 15,500 lbs. The promising Style Liner was intended for volume output and big sales by Federal standards, in fact something less than the all-out mass-production typical of the Big Three. The idea was a quality vehicle priced a shade higher than the Big Three's but with more generous specs and a wide range of features.

The Style Liner was the most costly Federal ever: tooling for the new and stylish cab and its associated (sheet-metal set the company back more than 1 million, which was a great deal of money for a small manufacturer in those days. Today of course this is about the outlay for, say, tooling for a truck lid or perhaps a hood. Seemingly Federal had an annual volume on the order of 4,000 or 5,000 units in mind with the new line though as it turned out sales were considerably less. "Times were changing very fast in the 1950s and I suppose the company could see that the future for an independent truck manufacturer of our size was uncertain at best. Besides, mergers, takeovers and big expansion programs were much in the wind during the early postwar years."

Lou Seaver remembers that the Style Liner was designed and styled in-house using company personnel, which was a change from earlier practice when Federal had enlisted the aid of stylist Henry Dreyfuss to update some of its models in 1937 and 1939. Seaver says that several styling consultants got wind of Federal's plans with the Style Liner and submitted proposals. "But in the end we decided we could do as good a job ourselves as we knew what we wanted and it was our own field." Federal possessed admirable facilities for the production of the new and radical all-steel cab, including a large hydraulic press for the output of one-piece roof panels: this had been purchased sometime earlier with the adoption of a similar roof for the existing cab. According to Seaver, the 2nd floor of the Federal plant housed the cab and sheetmetal shops, now much expanded and updated as a result of wartime production.

"Many special dies were cut and 'sunk' in preparation for the Style Liner," Seaver says, adding that tooling and planning took two years. "We put a tremendous effort into the new job." The Style Liner was a conventional-type but it embodied , a number of features which I were unusual for the time. "It was designed throughout for easy maintenance and servicing, the heart of which was the patented 'swing-lift' front fen der." This was a hinged portion of the fender which lifted upwards for easy access to the ; side lifting upper hood panel. Quick-release catches secured and held sheet-metal areas in i place.

The same ease of access was applied to the instrument panel, which was hinged and 1 tipped outwardly to expose the I instruments and the color-coded and separately fused wiring harness. The roomy cab was a wide 77-inches at the bottom where the flared sides enclosed the step-well and the battery i compartment. The new and stylish sheet-metal was backstopped by a rugged though conventional chassis offered in eight wheelbases (136 - to 250-inches) powered by L-head 96 and 131 horsepower Hercules gasoline engines. Federal always advertised on a substantial scale to back up the dealer force: the introduction of the Style Liner provided new opportunities in this line. Big double-page spreads were carried in a number of magazines while another novelty was support from Lowell Thomas, noted newscaster, with a sales brochure entitled "I Saw Motor Truck History in the Making," a venture much aided by Lou Seaver, by then Federal's assistant manager.

All in all the Style Liner was an attractive unit and hopes were high though it appears that sales fell short of expectations. Seaver recalls that a big, big problem developed which had nothing to do with the truck but nonetheless exerted a profound influence on its future - the outbreak of the Korean War in 1951. "The truck market softened almost immediately with the new uncertainties and of course it hit us at a particularly bad time with the introduction of the Style Liner." He remembers, too, that the automotive industry reverted to a war footing and posed more dislocation for the new truck. "Many of the components we needed went into short supply and we couldn't follow up orders with vehicles."

Seaver says vendors did what they could in meeting Federal's needs but supplies were uncertain and erratic at best. "Other manufacturers had the same problems," Seaver maintains, "and suppliers had to ration their output among all their customers with never enough for each." As a result production of the Style Liner was subject to fits and starts and orders for vehicles were delayed or went unfilled. Seaver candidly admits that Federal always had its eye on Diamond T, the firm's main rival. "Diamond T was a good competitor, in fact their trucks used many of the same components as ours." He believes Diamond T had more luck with major fleet accounts, a portion of the market where Federal sold fewer vehicles. "Diamond T had a first-rate dealer organization and of course it was an excellent product."

Federal continued to develop and produce the Style Liner series until the end of production in Detroit in 1954. The line was expanded with several new jobs, including one powered by a Continental engine and another by a Cummins JT, an early turbocharged diesel which posed some problems at the time. A former member of Federal's engineering team comments that the Style Liner's engine compartment proved too small for some of the larger diesel engines coming into vogue by the 1950s, in fact a circumstance other truck manufacturers had to deal with too. Federal's coverage of the post-war truck market Was complete, of course with the exception of the light duty units mentioned earlier, but there was one area where the company was absent, the COE field. Demands were developing for vehicles of this type, evident by White s success with its new unit, also by the gains of other manufacturers with their COE's and cab forward units. Admittedly this wasn't the largest portion of the heavy duty truck market but it was of growing importance.

Federal had an excellent COE before the war but it failed to reappear post-war, perhaps sidetracked with the company's emphasis on the Style Liner. Lou Seaver explains that there was no demand from Federal dealers for a COE though as noted rival truck producers did not overlook the COE's potential, many catering to this segment of the market with a succession of these units. The company took another close look at the truck scene in 1953, coming to the conclusion that its fortunes rested in an area it knew best, heavy duty units largely custom-built to customer specs. The lower and middle stratas of the market were crowded and hotly competitive but this was less the case among the "heavies."

"We turned to more military work," he says, "including special airfield tractors and some 600 Federal 60M refuelling trucks we supplied to the Air Force." Then, too, there was some diversification in the product line, namely chassis and carriers which Federal turned to in meeting requests from crane and hoist manufacturers. The truck crane had rapidly established itself as a useful and versatile aid in the construction industry and the manufacturers of cranes and hoists needed carriers. Seaver says that many were supplied to Warner & Swasey for the firm's "Grad-all." also to Shield for the Shield "Bantam" crane.

Another interesting development occurred around the same time: Federal was approached by the Freightliner Corporation, the object being the production of Freightliners in the Federal plant. Lou Seaver comments that the proposals were viewed with interest but the vehicle's all-aluminium cab and its rather specialized construction were not seen as particularly well adapted to Federal's facilities and production methods. Seaver also remembers that Sicard Limited, Montreal, entered into negotiations along similar lines though again nothing came of the discussions.

Federal production reflected the changes and the new emphasis on heavy duty and specialized vehicles. Output in 1953 was some 2,340 units, an improvement from the 1,662 they produced the year before. The figures for 1954 cover six months only and amount to 874 trucks, presumably a lapse posed by the sale of the operation to its new owners, Napco Industries Inc. The plant on Federal Avenue was rapidly cleared of its inventory, which was transferred to Minneapolis. It's reported that Federal's big 600-foot long assembly line - a costly installation - was disposed of to a truck manufacturer, or perhaps an assembler, in Turkey! Similarly, the Federal plant, or part of it, was later occupied by a furniture outfit.

What happened when Federal moved to Minneapolis is less clear. It appears some existing models were continued, though revised, using inventory from Detroit. Certainly these jobs - the Golden Eagle series - progressed far enough to warrant literature and elaborate specs. The "Federal" entry in "The Complete Encyclopaedia of Commercial Vehicles" - the "Truck Book" - accords Napco achieved some success with Federal vehicles in filling military orders though these, also some export jobs, were not enough to sustain production beyond 1959.

Federal Trucks in Australia

The Federal truck, as it was after World War 2, was the outcome of thirty-eight years' experience of building trucks for the varied needs of freight and passenger vehicle operators the world over. There were four basic models manufactured, each of which was available under a different model number with a two-speed back axle which increased its payload slightly. There were three optional wheelbases for the three bigger models and four for the smaller model. Thus all operators had a wide range from which to choose the most suitable vehicle for their class of work. For this review we will describe the model CM-80 4 ton truck, and the model CM-90 4.5 ton truck which was fitted with the two-speed back axle.

The trucks were available with either petrol or diesel engines, which were of Hercules manufacture. Of very solid construction, these engines featured a fully balanced crankshaft running in seven bronze-backed babbit metal main bearings, the big-end bearings being of the same construction. The side valves were of a then-new type of heat resistant alloy and were operated by high lift cams, which, in conjunction with large, individual porting gave very good breathing. Heavy duty aluminium alloy pistons coped readily with the powerful power strokes from the high compression combustion chambers. The water jackets were along the full length of the cylinders and provided adequate cooling under the most extreme conditions.

Specifications: Federal Trucks Model CM 80

Engine: 6 cylinder Hercules "L" head type J x BF. Bore and Stroke, 92 m.m. (3-1/8 in.) x 108 m.m. (4-1/4 in.) Capacity, 4,310 c.c. (263 cu. in.) Developed horsepower, 93 b.h.p. at 3,000 r.p.m. Compression ratio, 6.5 to 1.

Transmission: Clutch, Borg & Beck model 11 A6, single 11 in. dry plate with lining area of 131.4 sq. in. Gears, 4-speed Warner Model T9. Ratios, 4th, 1.001:1; 3rd, 1.69:1; 2nd, 3.09:1; 1st, 6.40:1; reverse, 7.82sl. Propeller shaft, open type with needle bearing universal joints.

Back Axle: Make-single speed Timken Model E-100 D.P.H. Track, 6 ft. 7 in. Ratio, 6.2:1.

Springs: Silico-manganese with auxiliary springs. Alloy steel heat treated U bolts and centre bolts; bronze "bushes.

Brakes: Timken dual primary hydraulic with vacuum self-contained power unit.

Front Axle: Make; Timken Model 3,000 3 H. Track, 6 ft. 2 is. I beam type.

Springs: Silico-manganese. Alloy steel heat-treated II bolts and centre bolts; bronze bushes.

Brakes: Lockheed hydraulic.

Steering: Gemmer Model 335, worm and roller type, 18.5:1 ratio.

Frame: Pressed steel channel section.

Wheels: Cast steel spoke, fitted with detachable 20 in. x 5.50 rims.

Dimensions: Wheelbase, 167 in., 180 in., 194 in. Gross weight-as truck, 15,000 lb., with trailer 27,000 lb.

Specifications: Federal Trucks Model CM 90

General specifications as for Model CM-80 with following exception -

Back Axle: Timken Model E-300 D.P.H. Two-speed, hypoid-helical, double reduction. Track, 67 in.

Rear Ratio: 6.13:1, 8.10:1.

Gross Weight: as truck, 17,000 lb. with trailer, 29,000 lb.