The Reliant Motor company thrived for over forty years, largely due to one, almost illogical, loophole in British legislation. At the time, provided a car weighed less than eight hundredweight and had three wheels, it was treated by the licensing authorities as a motor cycle. It could be driven by anyone with a motor cycle licence, without the need for a car license, and it was taxed as if it were a motor cycle and sidecar.

The Raleigh Cycle Company

The Reliant Car Company was formed in 1934 as a result of the Raleigh Cycle Company making the decision to discontinue production of their three-wheeled vehicles. The man who was at the time in charge of this section of the Raleigh Company, Mr T. L. Williams, saw a future for the development of the three-wheeler, and set up a company and workshop in the garden of his home in Tamworth, Staffordshire.

The

prototype Reliant three-wheeler van had its first licence stuck on its windscreen in January 1935. In the four years prior to the outbreak of World War 2, the product was developed in the light of practical experience - although it remained a fairly austere little vehicle. The original garden premises were soon out-grown, and a new site for a factory was found nearby at Two Gates. Offices were built, and plant constructed.

The Reliant Motor Company, although in future years never to reach a state of true volume production, nor ever really wanting to, was no longer a back-garden industry. This was obviously an unsettling time to be setting up a new motor company, and in the first month of the war the whole of the productive effort of the factory was diverted to engineering work under government contract.

Up until this time, Reliant had been using the

Austin Seven engine for their vehicles, but in the previous few years the company had developed their own 747 cc side-valve power unit. It was still very strongly based on the

Austin Seven engine which they had used until 1938, but it was a big step for such a small company to be manufacturing the engine for their vehicles as well as body and chassis components.

It was a policy of self-sufficiency which was to be maintained until some years later when the company began buying in power units for their four-wheeled sports cars. As with other car makers the war years were bleakly unproductive in terms of vehicle development, but the relatively young factory had plenty of opportunity to settle down and develop a working production line technique which would prove invaluable when the lines were again turned over to van production.

The First Reliant - The Regal

After the second world war Reliant resumed production of the three-wheeler van. But it was not until 1953 that Reliant produced their first passenger car. The most important step that the firm took was in deciding to investigate the possibilities of using fibreglass as a material for the car bodies. In 1956, the Reliant Regal was the first of their vehicles to emerge with a body of fibreglass moulding on an ash framework. The car had a chassis frame of box section side members and tubular cross members. The front cross tube carried a pivot for the front wheel suspension arm and a torsion bar spring inside the tube itself. The power unit - still the three bearing crankshaft side valve engine - and the radiator, were mounted behind the front wheel. The whole unit, clumsily concealed under a huge fibreglass tunnel, intruded considerably into the passenger space.

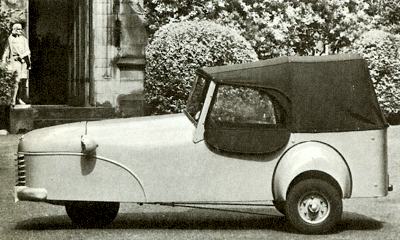

Reliant's sister company Bond built the MKB Mini during the 1950's.

Reliant's sister company Bond built the MKB Mini during the 1950's.

1950's Reliant 10 cwt van.

1950's Reliant 10 cwt van.

1950's Reliant 10 cwt van.

1950's Reliant 10 cwt van.

1961 Reliant Regal, which was fitted with a 750cc engine.

1961 Reliant Regal, which was fitted with a 750cc engine.

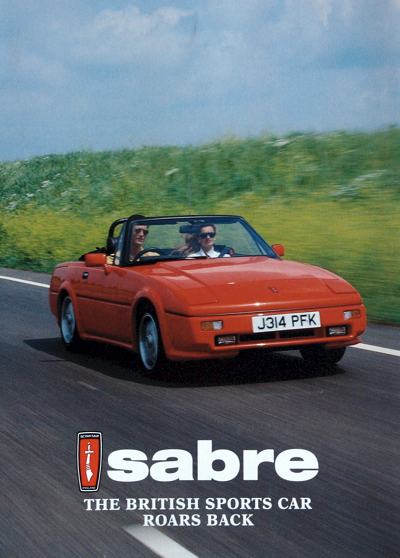

Reliant Sabre 1700cc Convertible.

Reliant Sabre 1700cc Convertible.

Reliant Sabre 1700cc Coupe.

Reliant Sabre 1700cc Coupe.

Bond Equipe, which was powered by a Triumph Spitfire 1147cc or 1296cc engine.

Bond Equipe, which was powered by a Triumph Spitfire 1147cc or 1296cc engine.

1969 Reliant Regal.

1969 Reliant Regal.

1970 Reliant Regal, which was in production until the Robin came in 1973.

1970 Reliant Regal, which was in production until the Robin came in 1973.

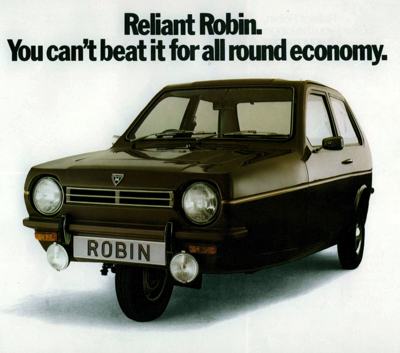

The Reliant Robin. The Reliant Robin.

Reliant Robin Interior. Reliant Robin Interior.

Reliant TW9 pick-up, the offspring of the company's relationship with Mebea of Athens (Greece).

Reliant TW9 pick-up, the offspring of the company's relationship with Mebea of Athens (Greece).

|

There was a normal open prop shaft which drove a live rear axle suspended from two leaf springs. The single front wheel was suspended by a leading arm and was sprung by the torsion bar inside the front cross tube. The interior trim was basic, the finish crude and the accommodation for rear passengers, very cramped, although, to be fair, the original concept was for a vehicle intended to carry two adults and two children. There were perspex rear and side windows (to save on weight) which could be opened either from the inside or the outside. But all round visibility was not good, even by the inadequate standards of the mid-fifties. It didn't help that the perspex side windows could be easily scratched as they were slid open and shut.

The early Regal was a very noisy vehicle - but the owner could console themselves with the thought that petrol consumption was usually no worse than about 45 mpg. Top speed was around 60 mph and as power output of the side-valve 750 cc engine was only 16 bhp and torque only a well-meaning 28 lb ft at 2,000 rpm, acceleration was not a strong point. The

steering of the early Regal was very high geared. It took only 1½ turns of the

steering wheel to go from lock to lock. This and the 26 ft turning circle, combined with the small overall dimensions, made it a handy, if slightly uncomfortable little car.

Reliant Switch to Unitary Body Construction

It was not until 1962 that the Regal was constructed with a

unitary body of fibreglass-reinforced polyester resin, known usually as GRP. To qualify for the licensing concessions there was a constant need to check that components and the finished vehicle were made to within very fine weight limitations. Unitary construction of fibreglass provided the lightest, most practical method of producing an

automobile for the budget end of the market. The six-acre glass-fibre moulding factory at Kettlebrook was acquired by Reliant after a fire destroyed a previous plant in 1966 and was turned into a purpose built plant employing, by the mid 1970's, nearly 450 people in 106,000 square feet of floor space.

The predominant process employed in the manufacture of body parts is the traditional one of building up layers of fibreglass and resin by hand to achieve a uniform thickness - although some components were produced by using matched dies and hot press mouldings. The rolls of fibreglass arrived from suppliers and were cut, sixty layers at a time, into patterns. At least two layers of mat were used in a body moulding and each three wheeler was composed of some one hundred and sixty mat patterns.

The fibreglass generally used had a tensile strength of up to 400,000 lbs per square inch. In the three-wheeler production shop there were tracked production lines of finished inner and outer body moulds. The moulds were washed, dried, polished, gel-coated with a polyester resin and cured between each process. A mould was ready about every twelve minutes. Resin with catalyst was added followed by 'laying up' the fibreglass sheets while the resin was worked into them. The line was arranged so that moulds could be revolved through three hundred and sixty degrees, then the sides, roof and floor could be built up conveniently.

There were very close weight tolerances and each component was checked to ensure that it is within the weight limits. Body mouldings were then moved to the trim shop where excess material was cut away, edges sanded smooth and holes for electrical and other fittings drilled. After cleansing, outer bodies were heated in an oven to reveal any air bubbles, imperfections were remedied with filler and doors and bonnets were mounted on the bodies before they are despatched to the assembly plant at Two Gates.

That the fibreglass method of body construction did not require the use of heavy power machinery or presses was the major factor which spurred Reliant to develop the idea of setting up a 'package deal' motor industry concept. This enabled an overseas manufacturer to set up their own Reliant plant relatively painlessly - particularly valuable for less industrialised countries. With this sort of deal, and with only a low capital investment, manufacturers could achieve profitable production at minimal outlay, something like 1000 units per annum were viable, it was claimed. There was also the advantage that bodies were manufactured locally and therefore a high percentage of the labour force was local. Also, vehicles could be adapted at the production stage to ensure that they are suited to local conditions.

Autocars Ltd of Haifa, and the Reliant Sabre

We dont know if the 1000 units per annum was actually achieved, but the first working example of this scheme was put into operation in Israel. In the late 'fifties, the political and social climate in Israel was ideal, and between 1958 and 1962 Reliant designed three vehicles for Autocars Ltd, of Haifa. They were the Sussita station wagon, the Carmel economy family saloon and the Sabra sports car. The most interesting of these was the Sabra - or Sabre as it was known in the United Kingdom.

The Sabre was first presented to a somewhat bemused and generally unimpressed British motoring public at the 1961 Earls Court Show. It had the distinction of being the first four-wheeler to be produced by Reliant. In appearance it was somewhat ugly with a very pronounced droop snoot bonnet and very untidy detail design. Drawing on experience gained from production of the three-wheelers, the car was manufactured from glass-fibre with a simple chassis frame of parallel boxed side members and cross members. The body was mounted on outriggers. The front suspension design was unusual in that it consisted of leading arms with very long pivot bearings - the geometrical effect being theoretically similar to a swing axle set-up.

At the rear there was a beam axle on coil springs located by a sort of Watt linkage which was unusual in that it was mounted fore and aft rather than transversely. Steering on the Sabre was by rack and pinion and there were disc

brakes at the front and drums at the rear. Reliant had fitted a Ford Consul 1703 cc engine into the car, but there were a variety of degrees of tune offered. An unexpected refinement was the well German ZF gearbox which had

synchromesh on all four cogs - something not all could boast in the early 1960's. Unfortunately, the car suffered from severe scuttle shake over bad surfaces and, perhaps because of this, very few were to survive. The Sabre was not cheap and it did not sell very successfully.

The Reliant Sabre Six GT

In 1963 the Sabre was completely redesigned and the resultant car, the Sabre Six GT, was much more successful and attractive. The body shape was cleaned up considerably and much of the original Sabre chassis was scrapped. The front suspension was of more straightforward wishbone and coil spring design. In fact, it used the same units as the

Triumph TR4. At the back, the original coil spring and longitudinal Watt linkage was retained. The uninspiring Ford Consul engine was superseded by the more lusty Ford Zodiac 2.6-litre unit, but unfortunately the excellent ZF box was ousted by the cheaper and standard Ford one - usually with an overdrive.

The Sabre Six was generally good for about 110 mph and acceleration was reasonable. The car had quite good

handling properties for its time and retained the disc/drum brake set-up of the earlier Sabre. After Israel, the next country to get a Reliant package deal was Turkey. The

Otosan Anadol was based upon an experimental Reliant vehicle, the FW 5. The Anadol was produced by

Otosan of Istanbul after approval for its production was obtained from the Turkish Government in February 1966. It was the first car ever to be produced in Turkey.

Mebea of Athens

By December 1966, the first Anadols were being made in a specially constructed factory although, initially, output was only about twenty vehicles per week. By the end of 1973, production had increased to around 10,000 vehicles per year. Otosan also made Reliant-designed cabs for Ford D type trucks since 1966. A package deal was sold to Greece in 1969 for the manufacture of the Reliant TW9 pick-up - a three wheeled vehicle with capacity for a 16 cwt payload. The little truck was made by the Mebea Company of Athens.

By the late 1950's it was apparent that if the Reliant Regal three-wheeler was to remain competitive in the UK more weight would have to be saved in the engine compartment and spent on trim and general finish. Also, the old side-valve engine could no longer deliver the performance of contemporary four-wheelers. The days of the old side-valve Austin Seven based 750 cc unit were numbered. There was no suitable engine being produced by any other manufacturer at this time, so the decision was taken to go ahead with the design and development of a completely new engine.

The Reliant Regal 3/25

It was not until 1962 that the company were able to put into production at Tamworth the result of this development work. This was a 600 cc four-cylinder push-rod engine with a combined cylinder block and crank case. There was a conventional, detachable head and the entire unit was of light alloy. The first Reliant model to be fitted with the new unit was the Regal 3/25 which brought the three-wheeler range a little closer in terms of trim, equipment, and performance, to contemporary small four-wheeler sedans. At this time the engineering factory at Tamworth was stretched to full capacity and as a result additional premises were bought seven miles away at Shenstone. The 93,000 square feet plant was opened in 1963 by

Jim CIark.

The Reliant Rebel 600

The Rebel represented Reliant's first serious venture in the four-wheeler economy car market. Introduced as the Rebel 600 in 1964, it was available as a sedan or an wagon car. The Rebel 700 replaced the 600 in 1967 and with the 701 cc alloy engine it was capable of about 70 mph and 40 mpg on average. Suspension was by coil springs and wishbones at the front with a beam axle and leaf springs at the back. The Rebel followed established Reliant tradition by being of glass fibre construction with a separate pressed steel chassis. In 1969, Reliant acquired Bond Cars Ltd and the following year the Bond Bug two seater was announced.

The Reliant Robin and Scimitar

Then, in October 1973, as part of a general expansion plan, the Robin three-wheeler was announced as a replacement for the Regal which had grown decidedly long in the tooth and low in appeal. The Reliant range of models is very rare in the motor industry in that it includes economy vehicles and a desirable and quite prestigious coupe-but nothing really in between. The GTE on sale in 1978 was derived directly from the original Scimitar introduced in 1964. The Scimitar was designed by David Ogle and represented the real breakthrough into the sports car market that Reliant had hoped for, but failed to achieve, with the earlier Sabres.

In its 1978 form, as the Scimitar GTE, it combined hatchback car space with excellent handling. It was perhaps about as far away from the basic, original three-wheeler Reliant concept as it was possible to get. It used the muscular Ford 3-Iitre V6 which pushed out 135 bhp, and top speed was in the region of 120 mph. The chassis was of boxed section pressed steel with tubular braced cross members. Steering was by rack and pinion and suspension was wishbones and coil springs at the front with an

anti-roll bar, and by coil springs, trailing arms and Watt linkage at the rear. The Watt linkage on the Scimitar was of the conventional transverse type as against the peculiar longitudinal system which was employed on the earlier Sabre and Sabre Six.

By October 1973, Reliant had undertaken the first stage of a UK£1,750,000 expansion programme which increased the productivity of all Reliant's plants. This was also the year of the Robin. The bodyshell was a completely new shape and, as before, it was mounted on a boxed section pressed steel chassis frame with tubular cross members. The single front wheel was suspended on a leading arm sprung by a coil spring and at the rear the beam axle was hung from a leaf spring with double acting shock absorbers and an

anti-roll bar. The 748cc engine then produced 32 bhp at 5500 rpm in the Robin and the gearing was such that 1000 rpm in top gear resulted in a road speed of 15.5 mph.

The old mid-'fifties Regal previously mentioned only managed 12.9 mph at the same engine speed. The unit still retained the removable wet liners in each cylinder and the three bearing crankshaft. The reasonably good looking body of the Robin was also designed by David Ogle and most motoring journalists believed Reliant were aiming for a slightly more up market image for the three-wheeler (even Princess Anne had a Robin). But the interior trim and equipment was far more attractive and better thought out than the previous three-wheelers by Reliant.

The Reliant Kitten

Pricewise it then came hard up against competition from small four-wheelers. It was not cheap and its appeal now depended even more than ever upon the idiosyncrasies of the vehicle licensing authorities. But while the Robin could be driven on a motor bike licence, it would probably sell. Van and Wagon variants followed and maintained interest in Reliant's economy cars until the launch of the Kitten - essentially a four-wheeled Robin; a 'proper' car with three-wheel frugality. Again, it was produced in sedan, wagon and van versions and might easily have laid claim to being the ultimate city car with its ultra-compact dimensions, 24 feet turning circle and 30 cubic feet luggage capacity. In the absence of a modern Mini, the Kitten filled a gap in the rock bottom motoring market. It was basically unsophisticated, but Reliant showed a commendable attention to its interior detailing which gave it a slightly up-market image.

By 1978 the factory was employing around 300 workers plus about thirty administrative staff to produce 17,000 engine and gear box units tor the various small Reliant models. (Scimitar components were also assembled here at the rate of about 3000 units per year). About 50 per cent of the mechanical parts for the smaller Reliant models were manufactured at Shenstone where the factory had a 40,000 square feet main engineering workshop which had the capacity to produce more than 400 engines, transmissions and suspensions weekly. Cylinder heads and blocks, crankshafts, camshafts and con-rods all moved along the production lines and components for engines, gearboxes, rear axles and front suspensions were all processed in various sections of the shop.

Gear cutting was also carried out at Shenstone. The cogs for the differentials and gearboxes were all cut at this factory. Reliant also designed all their own jigs and fixtures in the Shenstone drawing office and they were produced in the plant's tool room. Dynamos, starters, and brake components, however, were bought in from outside contractors. The Two Gates factory at Tamworth was on the site of the old Midland Red bus garage and it was the place where Reliant production first started. It was also the place where all Reliant vehicle chassis were built and where bodies from Kettlebrook and engines from Shenstone came together for assembly into finished three-wheelers and Scimitars.

Chassis pressings were made by a subsidiary of Reliant, Press Operations Ltd. On arrival they were welded and coated with protective paint in a dipping plant. The body shells from Kettlebrook travelled along rails, were painted and final assembly took place on twinned conveyors. There was a final assembly area in which each three-wheeler was checked to make sure that it did not exceed the eight hundredweight limit. By the late 1970's Reliant were part of the Hodge' Group and the parent company was the Standard and Chartered Banking Group. The founder of the Hodge Group, Sir Julian Hodge, was also Chairman of the Reliant Motor Group and of the Reliant Motor Company.

The Reliant Rialto

In 1981 Reliant introduced the wedge-shaped Rialto which whilst still used the 850cc engine, but it now featured a galvanised chassis. But the reputation of Reliant had been built on the Robin, and so in 1989 the Reliant Robin Mk 2 was introduced. The 1990’s were a turbulent time for Reliant who called in the receivers on 0ctober 25th 1990. Owners included Beans Engineering (for approximately 4 years), the Avonex Group and, by 1996 a small group banded togther to keep the marque alive. Amazingly they were able to get production sorted and, in the first full year 720 cars were built - and Reliant even managed to expand into lightweight commercial vehicles.

By 1999 Reliant had also moved into import and distribution with various new models that included the Ligier Microcar from France, the Piaggio Ape commercial vehicle from Italy. Not surprisingly, Reliant ceased making 3-wheelers in February 2001. To mark 65 years (though it was actually 66 years by the time the last Reliant was made) of 3-wheeler production Reliant built 65 Special Edition Robins, aptly called the Robin 65, that were individually numbered with a plaque on the dashboard. The last Reliant Robin was collected by its owner on February 14th 2001.

That year production rights for the Reliant Robin were sold to a Sudbury-based firm called B&N Plastics, but production ceased in 2002. Reliant concentrated on importing "speciality" vehicles from European manufacturers, including Piaggio, Bultaco and Ligier. The firm had plans to import the Indian San Storm sports car, but this plan never came to fruition. Soon after, they existed only as a spare parts manufacturer.

Reliant Models:

- Regal 1951-1972 and Supervan III

- Sabre 1961-1964

- Scimitar GT 1964-1970

- Rebel 1964-1973

- FW5 1966-1975

- TW9 1967-1987

- Scimitar GTE/GTC 1968-1982

- Robin 1973-1981, 1989-2002

- Kitten 1975-1982

- FW11 1977

- Rialto 1981-1998

- Fox 1983-1990

- Scimitar SS1 1984-1990

- Scimitar SST 1990-1992

- Scimitar Sabre 1992-1995