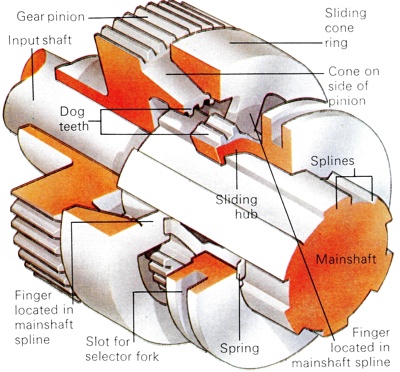

The cone on the gears used in the GM system has a set of dog teeth cut on ints internal surface. The sliding cone is carried on three fingers that locate in splines in the mainshaft. The second set of dog teeth is cut in a sliding hub, which is also slotted to receive the fingers that support the cone.

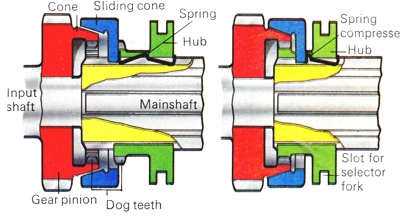

With the assembly in neutral (left) springs hold the components in place. The hub is then moved, and it butts against the cone's fingers, so forcing the cones together. As the speeds synchronize the fingers and slots in the hub align, allowing the hub to slide forward (right) and engage the gear's dog teeth.

|

General Motors' Synchromesh

The General Motors' design was one of the earliest synchromesh mechanisms to incorporate a baulking device and it has been widely used on Vauxhall cars and those produced by other General Motors' subsidiaries, though it has now been largely superseded by the baulk ring design. The design is best understood by reference to the engagement of direct-drive top gear in an orthodox layshaft gearbox.

The pinion on the input shaft again has a ringed extension that passes over the mainshaft. This extension has a conical outer surface and teeth are cut on its inner circumference. The other cone ring is carried on the mainshaft by three inwardly-projecting fingers. These fingers are narrower than the mainshaft splines with which they engage, so, although the cone ring has to revolve with the shaft, it does have some freedom of movement.

The second cone is therefore in light but permanent contact with the cone on the gear pinion and it is carried on the projecting fingers. As the shaft and cone run together, the fingers of the cone are brought hard up against the edge of the mainshaft splines. Behind the fingers and splined to the mainshaft is the sliding member of the synchromesh assembly. Integral with the sliding member, at the end nearest the pinion, is a ring of teeth which match those which are inside the pinion's cone.

Three open-ended slots are cut into the sliding member. They, too, are narrower than the mainshaft splines but are a little wider than the fingers to allow them to enter the slots when necessary. The entry corners of the slots are bevelled, as are the corners of the fingers.

Completing the assembly is a series of tongue-shaped springs which, when they are installed between the cone ring and the sliding member, locate the former correctly when the synchromesh is in the disengaged position. In this situation the two sets of dog teeth are, of course, clear of each other but the two cones are, as already mentioned, in light rubbing contact. The gear lever then moves the sliding member along the mainshaft towards the constant-mesh pinion on the input shaft.

The initial movement of the sliding member puts more pressure on the cones, as the corners of the slots bear against the cone's fingers and force it into firm contact with the pinion's cone. In this condition, the greater the force on the gear lever, the higher the pressure on the cones, and this ensures speedier synchronization. This constitutes the baulking device. As soon as the cones reach the same speed the drag between them ceases.

Consequently, the fingers are no longer pressed against the sides of the mainshaft splines. The gear lever's force on the sliding member causes the cone's fingers to enter the slots. The member continues its travel and brings its dogs into engagement with those on the gear pinion.