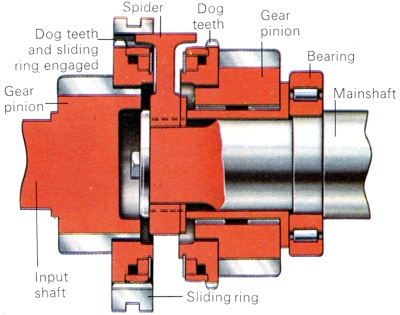

The gears used in the Porsche Synchromesh system each carry a ring of dog teeth. Below each set of teeth is a split ring with a conical edge. The teeth that engage those on the gears are cut into a sliding ring that is carried on a "spider" splined to the mainshaft of the gearbox.

The Porsche synchro system on third and fourth gears, shown here in neutral. The sliding ring is held clear of the gear pinions by a selector fork that locates in a slot around the edge of the ring. When a gear is to be engaged the sliding ring is moved forward until it conacts the split ring on the gear concerned.

The contact between the sliding ring and the split ring on the side of the gear synchronizes the speeds of the two shafts. The sliding ring then moves right over the split ring and its teeth engage the dog teeth on the gear. This therefore locks the two shafts together.

|

Porsche Split-Ring Synchromesh

The Porsche system was patented in 1947 by Dr Ferdinand Porsche, a German engineer renowned for his own high-performance cars as well as for having designed the original Volkswagen car. Dr Porsche produced the design specifically for the Cisitalia racing car of that era but the principle has since been applied, with amendments, by numerous other car manufacturers.

Apart from its undoubted efficiency, the Porsche layout has the advantage of compactness, allowing the gearbox to be relatively short and the three shafts to be correspondingly shorter and stiffer than those on other gearboxes.

It is simplest to describe the layout of Porsche synchromesh if it is applied to the third and fourth gears of a four-speed gearbox. Between the input shaft pinion and the third-gear pinion on the mainshaft a "spider" is solidly mounted on the mainshaft. The spider has three equally-spaced radial projections.

These projections have feet which are a sliding fit in slots cut into an internally toothed ring. Both ends of the teeth have a shallow taper, thus forming two outward-facing cones. On the outside of the ring are ribs that carry the gear selector fork.

The two gear pinions have the usual externally toothed dog clutch member, the teeth of which correspond to those within the sliding ring. Each of the pinions also has an extended hub which carries a gapped or split ring known as the "Porsche ring" and this resembles a large-section piston ring.

The Porsche rings have conical outer surfaces which, in turn, correspond to the cones within the sliding ring. Since the rings taper slightly in thickness round their circumference, from the middle to the ends, they cannot be carried directly on the hubs of the dog clutch members since that would make their outer surfaces eccentric. Between the ring and the member is another ring with the appropriate eccentricity between its inner and outer surfaces, thus making the outside diameter of the Porsche ring coaxial with the shaft assembly. A key prevents the intermediate ring from rotating on the hub.

Diametrically opposite this key, on the outside of the intermediate ring, is a projection that fits into the gap of the Porsche ring. The latter is thus compelled to revolve with its pinion and dog clutch member but, however, the gap is significantly wider than the projection, allowing the Porsche ring some rotational freedom on the intermediate ring.

Thus, when the gear lever is moved from neutral towards one of the gear positions, the selector fork takes the sliding ring in the appropriate direction, bringing one of its internal cones into contact with the facing cone on the Porsche ring. The first effect of the friction between the cones is to rotate the Porsche ring by the amount necessary to take up the clearance between its gap and the projection on the intermediate ring.

Once one end of the Porsche ring has butted up against the projection, the rotational drag on the ring causes it to expand. Expansion of the ring in this manner has two results; it increases the pressure between the cone faces of the Porsche ring and the sliding ring and it prevents the latter from moving any further towards the dog clutch teeth.

The tapering thickness of the Porsche ring makes it exert an equal outward thrust all round its circumference when it is expanded. Increasing the force applied to the gear lever merely raises the pressure between the cones, thus helping synchronization of the speeds. When synchronization is achieved, the frictional drag on the Porsche ring disappears, so that the ring is no longer expanded. The effort on the lever then causes the sliding ring's cone to exert a wedging action on the Porsche ring, thereby forcing down the intermediate ring and reducing the Porsche ring's diameter enough for the sliding ring to pass outside it and engage the teeth of the dog clutch member.