Fuel Gauges

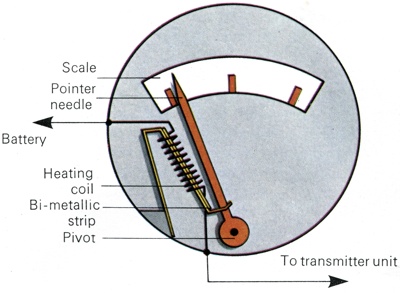

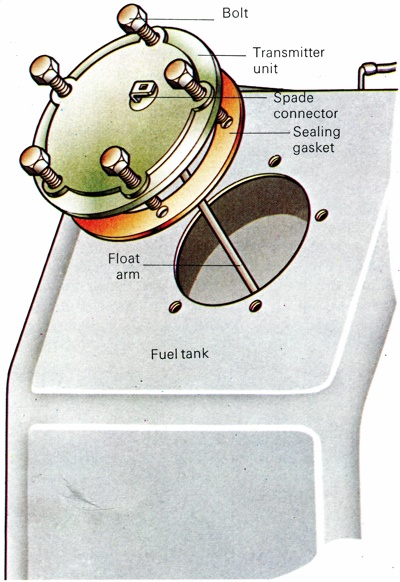

The fuel gauge usually consists of two main components, the transmitter in the boot and the dial face mounted on the car fascia. The transmitter acts as a rheostat or "variable resistance" and consists basically of a float and a lever which change position according to the amount of fuel in the car's petrol tank. There are two basic types of fuel gauge on older cars, a bi-metallic resistance gauge and a magnetic or moving-iron gauge. Inside the bi-metallic gauge there is a small heating coil surrounding a strip of metal which is made up of two pieces of different metal riveted together.

When the ignition is switched on, the heating coil causes the bimetallic strip to deflect. The movement of this strip is then transferred to the pointer needle of the gauge. The strip will deflect most when there is no resistance in the fuel gauge electrical circuit and the tank is full. The resistance in the circuit is at its maximum when the tank is empty which means that the strip will not alter its position and consequently the gauge will read zero.

The advantage with the bi-metallic gauge is that the reading of the gauge will not be affected by any movement of the fuel in the tank when the car is moving. On the other hand, this type of gauge is sensitive to fluctuations in the car's battery voltage and so a separate voltage stabilizer is usually incorporated into the fuel gauge circuit to keep the voltage and, therefore, the instrument reading, constant.

However, the

Citroen GS is one of the few cars which has a bi-metallic fuel gauge which is not controlled by a conventional voltage stabilizer. This voltage stabilizer, which is a small, sealed unit with a separate earth tag, can usually be found either on the back of the speedometer instrument on the printed-circuit board or mounted somewhere on the car body fairly close to the instruments.

Magnet Iron Type Fuel Gauge

The other type of fuel gauge, the magnetic or "moving-iron" type, can easily be recognized by the fact that its pointer needle gives an instant reading when the ignition is switched on, whereas the bi-metallic gauge moves slowly into position when the circuit is activated. The principal components of the magnetic gauge are two electro-magnets which act on a small armature and the gauge works in the following way. The armature is connected to the pointer needle of the gauge.

Bi-metallic strip type fuel gauge.

Magnetic type fuel gauge.

Fuel Gauge transponder unit, as found on older type Vauxhall and Fiat models. It was fixed to the tank by screw or hexagon-headed bolts.

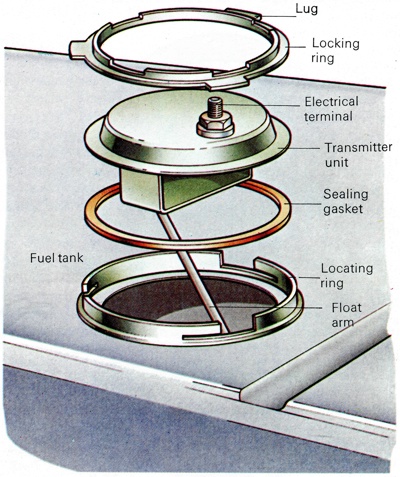

An inter-locking lug type fixing is used on older Ford and Datsun transmitter units. The locking ring has to be turned to enable the lugs to come free of the locating ring on the tank body. |

Current flows constantly through one of the electro-magnets, known as the control coil, when the ignition is switched on. The strength of the current flowing through the other electromagnet, the deflect coil, depends on the position of the float unit in the tank. With this type of gauge there is no resistance in the circuit when the tank is empty and so the armature and the pointer needle are drawn towards the deflect coil. But, when the tank is full, most of the current is diverted towards the control coil and, consequently, the pointer needle shows "full'.

The first check, if there is no reading on your fuel gauge, is to make sure there is sufficient petrol in the tank. This may seem very obvious but it is an easy point to overlook. Checking the electrical connections: Next, with either type of unit, make a thorough check of the wiring circuit of the fuel gauge. Ensure that the gauge is firmly located in position and that all of the electrical connections are tight. Look in your handbook to see if the fuel gauge is on the same circuit as any other components that are not working.

If this is the case the most likely cause of the failure is a blown fuse. Before you replace the fuse, however, check the cause of it blowing. You will usually find that one of the electrical leads has worn through and caused a short-circuit. If this is the case, replace the damaged section of wiring by cutting the damaged part out and then joining a new section of wire to the cut ends with in-line connectors. Any new lengths of wire should be of the same size and colour code as that which has been cut out.

Checking The Gauge

If the electrical wiring appears to be satisfactory move on to check the gauge itself. It is extremely important to bear in mind that gauges with voltage stabilizers should never be connected directly to the full battery voltage or they may be irreparably damaged. First, disconnect the battery and then remove the "T" terminal wire on the back of the instrument.

You may be able to do this by reaching behind the fascia or you may have to loosen the instrument clamping bracket and then push it forward from its mounting. Re-connect the battery and switch on the ignition. The gauge should now register full. If you then earth the "T" terminal, the gauge should register empty. With bi-metallic gauges which have no markings earth one terminal. The gauge should read "Empty" or "Full". Re-connect the lead and then earth the other terminal.

The gauge needle should, now move to the opposite extreme of the scale. If there is no change in the needle position the gauge must be replaced. Checking the transmitter unit: To check the transmitter unit, you must first ensure that the level of fuel in the petrol tank is below the level at which the transmitter unit is mounted to the tank. If necessary siphon the fuel out using a household siphon available from branches of large hardware stores.

You must now remove the transmitter unit. On most cars this can be done without the need to remove the tank and access may be through the boot floor, a side or rear panel, from under the car or under the rear seat. Work in a well-ventilated area and avoid smoking or the use of a naked flame. Disconnect the battery to avoid the possibility of an electrical spark creating a fire.

There are three common types of transmitter unit fixing, the retaining ring that is held in place by setscrews, interlocking lugs or a coarse screw thread. Undo the relevant fixing, taking care not to damage it and then lift out the transmitter unit. Check that the arm is free to move and that there is no fuel in the float. If there is any fuel in the float it will give an inaccurate reading. Replacement floats can be purchased separately.

Make sure that the wires are properly connected, the live feed should go to the "B" terminal of the gauge and the transmitter unit lead should go to the "T" terminal of the gauge. Connect a length of 14/0.012ins wire from the body of the transmitter unit to a good clean earth point on the car. Re-connect the battery and switch on the ignition. By moving the arm of the float you should find that the needle on the gauge will follow the arm position from "Full" to "Empty".

If the gauge reads only "Full' the transmitter unit is faulty and should be replaced. To re-fit the transmitter unit carefully clean away all traces of the old gasket and fit a new one, using a proprietary compound such as Loctite. Tighten the unit facings as much as possible and then allow the petrol fumes an hour or so in which to disperse before you test drive the car.

Checking the voltage stabilizer

Checking the voltage stabilizer applies only to bi-metallic gauges. If your car has a bi-metallic fuel gauge that does not register a reading, check that the water temperature gauge is working correctly. If it is not, this indicates that the voltage stabilizer is at fault. Another indication of voltage stabilizer trouble is an erratic needle on the gauge.

If you have checked all of the other possible causes of a fault and found the relevant items to be working properly, by a process of elimination the voltage stabilizer must be faulty. To check a voltage stabilizer you will need to know the voltage setting of the individual unit. You can establish whether or not the voltage stabilizer is working by using an ordinary test lamp.

Connect the lamp between a good earth and the "I" terminal on the stabilizer. If the unit has no markings, connect the lamp tp the terminal to which the lead from the instrument is joined. With the ignition switch on, the bulb should light but, even if the bulb does light, the voltage stabilizer may be out of adjustment internally. It is not possible to alter the setting of a voltage stabilizer and so a faulty unit must be replaced with a new, operative one.

To check the exact output of a voltage stabilizer you will need a bi-metallic or "hot wire" voltmeter which can operate at 5 volts. Another type of voltmeter will not be suitable as it will react too quickly to the output of the voltage stabilizer, which itself has a very quick on/off action, to give a prolonged reading. Consequently, you will need a bi-metallic meter which acts more slowly and gives an average reading of the output of the voltage stabilizer.

The voltmeter can be used in the same way as a test bulb in that one terminal is connected to earth and the other to the "I" terminal of the voltage stabilizer. Switch on the ignition and note the reading on the meter. If the reading is below the recommended operating figure a completely new unit must be obtained.

Also see: Auto Definitions - Fuel Gauge