We all know the Tacho, or rev counter, is an instrument for measuring the speed of an engines rotation. Unlike the speedometer, the tachometer is not a legal requirement and, while nearly every car built these days has one, there was a time when its use was restricted to sports, high-performance and expensive cars.

Being that it is one of the most important gauges in your instrument cluster, motoring enthusiasts would commonly fit after-market versions to their cars - and although the fitment of one would make your classic arguably less than stock, provided the tacho is from the same era it is well worth keeping (although you would want to check that the fitment of one would not reduce your score in any concours where the judges are looking strictly at stock application).

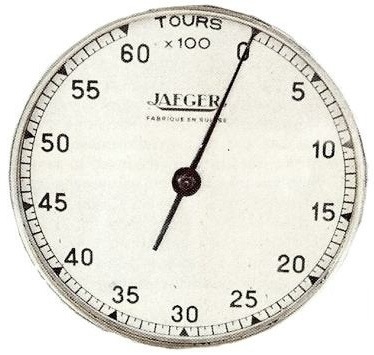

Early models of tachometers depended on a geared rotating mechanical drive taken from some moving part of the engine, such as the flywheel, camshaft, fan pulley, etc. The drive rotated a magnet, thus inducing eddy currents in an aluminium disc, much like a speedometer, but the scale was marked in revolutions per minute. The modern type tacho is electronic, operated by impulse from the low-tension 'make and break' of the distributor points.

The Impulse Tachometer

One of our favourites is the Smith's Industries version as fitted to the

E-Type Jaguar. This is a good example of the impulse tachometer. Two pairs of connections were required, one pair for the supply leads and the other for the pulse pick-up leads. The pulse leads were, in fact, one continuous wire with a loop (forming the primary winding of a transformer) taken around a soft iron core projecting from the rear of the tachometer casing. The advantages of this type of signal pick-up were that there was no break in the ignition wiring, so a break in the tachometer circuit would not affect the ignition; and that there is no direct electrical connection to the ignition from the tachometer circuit.

The secondary of the transformer, inside the tachometer case, was connected to a printed circuit that applied current pulses, originating from the distributor and therefore at a frequency depending on engine speed, to the indicating meter. The internal circuit was fed from the supply leads, one of which was taken to one of the vehicle's existing switched and fused circuits running back to the

battery, the other to earth (ground). Of the pulse leads, one was taken to the contact breaker (CB) terminal on the ignition coil, the other to the contact breaker (side) terminal on the distributor. The previously existing CB to distributor wiring was discarded. Note, however, that modern ignition coils, the SW and CB connections are marked' -' and' +' for positive earth systems and '+' and '-' for negative earth systems.

If a radio was fitted to the car, the CB to distributor wire may be a noise suppressor lead; if this is so, do not remove it, but instead, disconnect the wire leading to the SW terminal of the coil and connect the pulse coil of the tachometer between the end of this lead and the SW terminal. On some models of tachometer, separate leads are provided for internal illumination and must be taken to an existing lighting circuit. Fitting is well within the scope of the average motoring enthusiast and motor accessory shops usually have a range of tachometers available. Back in the 1960s and 1970s there were separate 4 and 6-cylinder models (suitable also for 2- and 3-cylinder 2-stroke engines respectively).

An aftermarket auxillary instrument cluster from Smiths, which featured and Ammeter and vacuum gauge in addition to a tacho.

An early tachometer from Jaeger of France.

A pair of tachometers typical of the aftermarket style fitted to cars during the 1960s and 1970s. |

One of the main uses of the tachometer is assisting the driver in correctly relating engine speed to road speed, so that gears can be changed at the optimum combination of these two factors, achieving the best power/speed ratio and the most economical use of fuel. Thus, ideally, the engine speed will, as far as possible, be held, through the gears, within the range 2000 to 3000 revs/min (rpm). Variations of these limits are of course possible, depending on the particular car; some manufacturers mark the tachometer with coloured segments related to the gear engaged. Although the tachometer is usually calibrated up to 8,000 or even 10,000 rpm, the maximum permissible speed for most engines is usually well below this figure.

Top Dead Centre

Some tachometers are provided with a red 'do not enter' segment; others have an adjustable red pointer to indicate the limit; but on no account should the manufacturer's recommended maximum speed be exceeded. When the engine is tuned, the distributor points must be set to open a certain number of degrees before TDC (top dead centre). Most manufacturers lay down the engine speed, or narrow range of speeds, at which this setting must, for maximum effectiveness, be undertaken. A common speed is around 800 rpm, but some makers lay down 1700 or even 3000 rpm. It is clearly not possible to attain these engine speeds accurately without a tachometer.

For small carburettor or distributor gap changes, the tachometer is far more sensitive than the vacuum gauge. If it appears that full power is not being obtained, perhaps due to a sticking valve, defective

piston ring or faulty sparking plug, the faulty cylinder can immediately be determined by shorting each plug to earth - taking care to grasp only the insulated handle of the screwdriver used for the purpose. The loss of each cylinder, as it is short-circuited, should produce exactly the same loss in rpm; if the loss of anyone cylinder shows a smaller dip on the tachometer pointer than the others, that one cylinder must be assumed to be defective in some way.

On diesel engines, which have no ignition system, the impulse tachometer cannot be used, but other types are available; for example, an insulated extension shaft, set with soft iron bars. Magnets or energized coils surround the shaft and more or less current is generated in proportion to the engine-speed. This type of ac generator may operate a de-moving coil type of meter through a rectifier, or it may drive a remote motor which in turn operates a mechanically driven instrument. Pulse generators, similar to a small ignition coil and having a mechanical or magnetic drive, are an alternative to the ac generator type.