|

Max Friz, the engineer who designed the BMW IIIa aero engine and the R32 motorcycle. |

BMW, as a marque, is mentioned relatively late in the course of automotive history. The first

automobile bearing the blue and white trademark spinning airscrew didn't appear until 1928. Nevertheless, after 50 years the Bavarian firm was able to look back upon a well-founded, world-wide reputation.

BMW created not only remarkably concieved and well-built automobiles of an above-average quality, but the company had also been very active in the fields of aircraft piston-engine, jet engine, motorcycle, commercial-vehicle engine and marine engine design and construction, where exceptional results had been achieved and valuable pioneering work accomplished. BMW's history, particularly over the first 50 years, had a three dimensional basis: air, water and land.

The company's technical proolucts were continuously above normal standards during its founding years and the quality of these constructions was demonstrated in countless motorsport events. During the first 48, the marque's laurels accounted for no less than 206 motorcycle world records, and 98 aircraft world records set with BMW engines, plus a series of automotive records, many hill-climb victories and hundreds of wins in races, rallies and cross-country events for motorcycles, sports cars and touring cars.

Many famous automotive marques were established on the basis of an earth-bound vehicle alone, whereas a large number was active only on the automotive sector but participated in the early development of aero engines as well. In a certain sense the cornerstone of BMW was the aeroplane or, better said, the early flying machine. Later on, the aero engine became a further predecessor of the marque which finally crystalized out of an aviation-oriented business partnership to devote its production programme to earth-bound vehicles and their motive sources.

The founder who staked his enterrprise's future on the aeroplane was Gustav Otto, the son of Nikolaus August Otto, inventor of the Otto engine. The date of the firm's birth was the 15th March, 1911 and it was called "Gustav Otto Flugmaschinenfabrik Munchen" (Gustav Otto Aircraft Works, Munich) being situated on the eastern periphery of Munich's Oberwiesenfeld Airport, on Lerrchenauer Strasse. On the 12th January, 1915, Otto changed the firm's name to " Otto-Werke, Gusstav Otto, Munchen " (Otto Works, Gustav Otto, Munich). Biplanes were primarily produced there.

The other founder was Karl Rapp, an engineer and constructor who, as chief company clerk, occupied an important position in the firm of "Flugwerk Deutschland GmbH" in Brand, near Aachen. He founded the "Rapp-Motoren-Werke" on the 28th October, 1913, with a capiital of 200,000 Marks provided by Munich businessmen. The compaany was located at Schleissheimer Strasse 288, in Munich's Milbertsshofen district, and produced marine and aero engines of its own design as well as constructions of other origin built under patent rights.

The outbreak of World War I was responsible for a rapid development of the aeroplane which, in turn, caused a huge expansion of the firms involved in its construction. It also affected the Otto Works which became reincorporated as the "Bayerische Flugzeuggwerke Aktiengesellschaft" (Bavarian Aircraft Works) on the 7th March, 1916, with a very substantial capital investment of one million Marks. As a result of this the workshops on Lerchenauer Strasse were considerably enlarged.

|

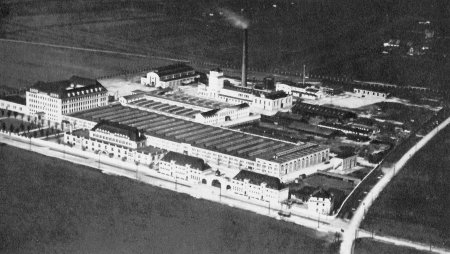

An aerial view of Bayerishe Motoren Werke, which were constructed in 1917/1918

at Moosacherstrasse and acquired by the South German Brake Company in 1922,

a subsidiary of Knorr Bremse AG. |

This reorganization of the 7th March, 1916, the date upon which the firm was incorporated, is that given as the founding date of BMW. However, a number of years was still to pass before the present firm was developed out of the consolidation of the "Bayerische Fluggzeugwerke Aktiengesellschaft" and Karl Rapp's "RappWerke". Since airframe and aero engine are the main components of the aeroplane, and as the first-named firm produced airframes and the latter aero angines, it was a logical step for the neighbouring "Rapp-Motoren-Werke" to deliver powerplants to Otto's company.

Through ever-rising demands for increased production during the second phase of the World War, Rapp was forced to expand his plant and so the" RappWerke" were also reincorporated during the summer of 1917 into the "Bayerischen Motoren-Werke GmbH" (Bavarian Motor Works Ltd.), specifically on the 21st July, 1917.

This new firm received a capital investment of 1.2 million Marks and the investor's name was Camillo Castiglioni. However this sum was insufficient to enable the necessary expansion of the construction facilities which was brought about by the great demands on material, so with a further investment of 12 million Marks or the 13th August, 1918, the firm was yet again reincorporated as the "Bayerische Motoren-Werke AG' (Bavarian Motor Works Company). Once more one of the principal stock holders was Camillio Castiglioni. Through this new investment the most modern German factory for the production of liquid cooled aero engines was built on the northern periphery of Oberwiesenfeld Airport. The employees, working in several shifts, numbered 3,400. The company went into liquidation, however, on the 19th August, 1918, the old facilities a Schleissheimer Strasse still being retained for a while to serve as design offices and experimental workshops, but they were sold later on. As BMW historian Herman Rauschert noted, there were intimate technical bonds between th "Bayerische Flugzeugwerke AG and the "Bayerische Motorenwerke AG", but none that could be classed of a financial nature.

The Treaty of Versailles

The Treaty of Versailles forbade the construction of aircraft in Germany and this fact caused a complex reorganization of both factories. The "Bayerische Motoren Werke AG" initially received an order for the construction of air

brakes for the German national railroad from the firm of "KnorrrBremse AG", while the "Bayerischen Flugzeugwerke AG" built motorcycles, tool-storage cabinets, office furniture and other items. In neither case could there be found a permanent solution to alleviate the production problems which were present. The answer was found in the person of the Viennese banker Camillo Castiglioni who aquired the "Bayerische Motoren Werke AG" for the inflationary price of 75 million Reichsmarks on the 20th May, 1922. He bought the company, 90% of whose stock lay in the hands of the "Knorr-Bremse AG", along with all its tools and machinery, at the same time also buying up the "Bayerischen Flugzeugwerke AG", on Lerchenauer Strasse, for 4 million Marks.

|

Looking none too happy, the destruction in 1922 of all components for

the BMW IIIa aero engine taking place under the supervision of

the Allied control commission. Completed units became war reperations. |

The shops of the "Bayerischen Motoren-Werke" which were situated nearby, on Moosacherstrasse, as well as the manuufacture of brakes, were retained by "Knorr-Bremse AG", the subsidiary firm being renamed as "Suddeutsche Bremsen AG" (South German Brake Company). Castiiglioni's newly aquired engine-construction facilities were fully incorporated into the "Bayerischen Flugzeugwerke AG", the airframe factory, with the newly christened firm being called "Bayerische Motoren-Werke AG". In this manner the founding date of the "Bayerischen Flugzeugwerke AG" also became, indirectly, the birthdate of the new firm of "Bayerische Motoren-Werke AG".

The history of BMW's technical development doesn't begin on that 20th May, 1922, when Castiglioni aquired the firm's name as well as the aero engine factory - it commmenced with the incorporation of the "Rapp-Motoren-Werke" into the "Bayerischen Motoren-Werke GmbH" on the 21st July, 1917, for it was in this newly created firm that the BMW IIIa aero engine was developed, which, in further modified form, was responsible for a world's record and therefore was indicative of BMW's future path - a path drawn in red ink throughout the young marque's future, namely, the proof of technical pre-eminence through extraordinary demonstrations of performance leading to victories in sports events.

During the middle of the war a young Swabian engineer named Max Friz entered into the employ of the "Rapp-Motoren-Werke" and brought the plans for a high-altitude aero engine along with him from his former employers, the "Daimler-Motoren-Werken ", where he hadn't been able to convince the management to build the powerplant. Friz had, incidentally, also worked on the development of the 1914 Mercedes

Grand Prix engine. However, Karl Rapp had other things to occupy Friz's time, at first, than the construction of a totally new engine, pressing and difficult technical problems which had to be solved taking primary priority.

At that time Rapp was also building engines for the Austrian navy, and the technical inspector responsible for their acceptance was an Austrian engineer named Popp. He immediately recognized Friz's capabilities and when Rapp's firm needed financial assistance, Popp contacted his friend Castiglioni. Rapp left the firm which, under its name of BMW had two new partners: Popp and Castiglioni. Friz's new aero engine ran on the test bench in November, 1917. It was a water-cooled, 6-cylinder, in-line unit of 19 litres displacement develloping 185 bhp and its type designation was BMW IIIa. The young engineer had great difficulty in finding a test pilot willing to take the new machine up but he finally succeeded in his efforts to convince the sceptics and went along on the flight as passenger. The government officials were duly impressed by the engine's performance and 2000 units of this type were ordered, the first series being delivered to von Richthofen's famous fighter squadron. Ernst Udet, one of the pilots in von Richtthofen's "Flying Circus", was later to comment with great enthuusiasm on the BMW IIIa's performance capabilities.

|

Franz Diemer piloted this DFW C 4 biplane, powered by a BMW IV aero engine,

to an unofficial altiitude record on the 17th June, 1919.

Diemer attained the record height of 9,760 metres in 89 minutes and

only the lack of an oxygen mask precluded the

breakthrough of the 10,000 metre mark. |

The demand for this engine grew to such an extent that new factory buildings had to be constructed, and following this a new company founded: "Bayerische Motorenwas Werke AG". Even before the change took place, Friz had modiified the BMW IIIa and considerably increased its high-altitude perrformance through the utilization of a supercharger. In this form the engine was designated the BMW IV, but as the war entered its closing stage only 70 of the 2,000 units ordered had been delivered.

Germany Banned From Building Military Aircraft

With the lost war came the ban on building military aircraft, but BMW still had hopes of building aero engines for commercial use. The victorious powers, however, were of another opinion and the destrucction of all machines and machine tools was ordered. Among the components was a large number of connecting rods which the techhnical commission also ordered to be destroyed.

It was only natural that the BMW technicians were loath to comply with this wish and as no other solution was found to be suitable, the officers of the commmission decided that the connectting rods should be pounded to pulp on the same presses normally utilized in the production of engine components. The BMW technicians agreed but through a bit of clever, and not entirely humourless chicanery, utilized base plates which were exactly commensurate to the connecting rod's dimensions!

Rod upon rod was placed under the presses to be removed in one, undamaged piece immediately afterwards. It was then planned to utilize these connecting rods in automotive engines and, furthermore, a way was found in which to complete the development of the BMW IV aero engine. This having been accomplished practical proof of the unit's performance had to be obtained. A DFW C IV biplane still sat on the Oberwiesenfeld Airport apron and the new engine was installed in great haste. A pilot was found who would undertake a record flight: Lieutenant Zeno Diemer.

Taking off on the 9th May, 1919, Diemer attained the impresssive altitude of 9,700 metres, and on the 17th June he bettered that figure to reach a height of 9,760 metres. This altitude record was never officially recognized though, since Germany wasn't a member of the FAI at the time and there were no officials of that organizaation present while the flight was taking place. The validity of the record was nevertheless unofficially established since two barographs were on board the aircraft, and their accuracy was substantiated by Dr. Schmauss, director of the state weather-bureau.

The BMW IVa aero engine, as the latest version was designated, was also a 6-cylinder in-line unit and its 22-litre displacement produced 250 bhp at first, later on yielding 320 bhp. One can only marvel at the techiical zeal shown by these men who, at a time of almost complete political confusion and with the prospects of an uncertain future, possessed the temerity to plan a record flight. It was, in a manner of speaking, a final grandiose demonstration before closing shop. All completed BMW IV powerplants, as well as all of the techniical drawings, plans and blueprints were to be delivered to the Allied technical commission, under offiicial orders. It became a prime necessity to bridge the uncertain times ahead in order to retain the works' technicians and labour force.

Manufacturing Air Brakes

Since the German national railroad was changing over to air

brakes for all its rolling stock at that time, sufficient work was on hand. BMW received a contract for the construction of Kunze-Knorr air

brakes - but BMW was an aero engine factory. Since it was forbidden to build these powerplants the designers looked around for possibilities of engine utilization on land and water. A 4-cylinder marine engine was designed and constructed, having a power output of 45 to 60 bhp, and it was simultaneously utilized as a motive source for trucks, buses, powered ploughs and also as a stationary powerrplant. These engines were of an extremely high quality and possesssed an exceptionally long lifespan. Some thirty years later, spare-parts orders were still being received at the factory, proving that many of these units were still in use!

In 1921 a 500cc opposed twin was introduced - the M 2 B15. Employed at first as a stationary powerplant, it was afterwards installed as a proprietary engine in various motorrcycle frames, but mainly in the line produced by the Victoria works in Nürnberg. All these proprietary power-units were known under the trademark of "Bayernmotor". The" Bayerischen Flugzeugwerke AG", during the time of bridging the production gap, built a motorrcycle frame in which the BMW M 2 B15 "Bayernmotor" was mounted. Contrary to the future policy of mounting the engine horizontally and at a right angle to the longitudinal frame axis, which was to become traditional with the BMW twin-cylinder motorcycles, the powerplant was mounted parallel to the frame's longitudinal axis, with a belt drive to the rear wheel. Its trade name was "Helios ". Also in the production programme was a light motorcycle powered by a single-cylinder, two-stroke engine. Designed by Curt Hanffland, of Berlin, it was known as the "

Flink", which means speedy, and could be viewed as an ancestor of today's moped.

As great quantities of sheet metal and plywood were still on hand from the war-time aeroplane construction stocks, various items such as tool-storage cabinets, office furniture, etc. were built in addition to the motorcycle frames. In this manner both factories were able to successfully survive the precarious years until the cornerstone for a fresh beginning was layed on the 20th of May, 1922, through Camillo Castiglioni's transactions.

A New Beginning

The new beginning was not easy. Money was short. The modern foundry was located on Moossacherstrasse while the works on Lerchenauer Strasse were dependent on the deliveries of subcontractors. Furthermore, the buildings which Castiglioni had aquired along with the property were, for the most part, lightly built, single-story, wooden connstructions, only the massively built office building on the street being of stone. It was once again Max Friz who provided the impetus for a really new and fresh start. Friz was the firm's chief engineer, and the forrmer Austrian technical inspector and engineer, Popp, who was also a close friend of Castiglioni, was the director.

Popp assigned the rather dull job of modifying the Helios motorcycle to Friz, who undertook the project with less than enthusiasm. The stock of Helios frames which had come to the new company along with the airframe factory was difficult to get rid of as the Hellos possessed a very poor roadability. However, Friz was able to turn the trick and his modifications succeeded in getting rid of the Helios backlog and also prompted the gifted engineer to undertake the design of a brand-new motorcycle. In this manner the BMW R32 was born, a machine which not only caused a considerable stir of excitement upon its premiere at the 1923 Paris Salori, but also established the BMW tradition in the motorcycle field.

Its

air-cooled "flat twin" developed 8.5 bhp from a 500cc displacement and was mounted with its crankshaft in the longitudinal plane of the tubular-steel frame. The rear wheel was driven via a shaft. Just as he had previously done with his first aero engine, Friz tested the new motorcycle personally, taking part in the "Reliability Run Through Bavaria's Mountains" and reaching the finish without trouble, but also without attracting too much attention or causing a stir.

Nine different motorcycle types were produced up until 1928 and a total of 27,875 machines were sold. During the same period no less than 573 racing victories went to BMW motorcycles on Europe's race courses. BMW's reputation for extraordinary performance in the motorcycle field had been lanced and become well established. The high point, however, was to be attained at a later date. At that same time the aero engine was making a comeback. Through war-reparation deliveries BMW engines had become world renowned and especially the BMW IV, with its 310 bhp output had become increasingly popular.

Waiter Mitttelholzer, the well-known Swiss pilot, undertook a series of remarkable Alpine flights utilizing this powerplant. Among other aircraft, he piloted a Junkers Ju 20 powered by a BMW IV engine in 1924 and established a total flight time of 41 hours from Zurich to Teheran carrying a cargo load of 1,600 lb. and reaching an altitude of 6000 metres. The BMW IV was also widely used in mail planes and on South Ameriican runs established the remarkable record of 500 to 800 flight hours before a general overhaul was necessary.

|

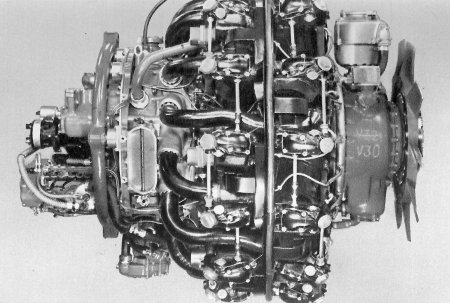

The 801 Aero Engine was a 14 cylinder, twin-row radial unit with BMW's

newly developed command regulator which automatically

controlled various components. its capacity was 41,811cc... |

When the ban on German aircraft construction was finally lifted BMW was ready with a V12 liquid-cooled aero engine which had a maximum power output of 750 bhp and prooduced 550 bhp at cruising speed, in the year 1929.

Max Friz had been responsible for its design and it was produced until 1939. Countless world records and long-distance flights were attained with aircraft and flying boats powered by the BMW VI. The thousandth unit was produced by 1930 and in 1932, German aviator Wolfgang von Groonau undertook a flight around the world in a Dornier Wal which was powered by a modified version of the BMW VI.

BMW received the license to produce the

air-cooled, 9-cylinder radial engine designated Hornet A from the American firm of Pratt & Whitney in 1928. This copy of the American engine was designated BMW Hornet and found its primary use in the three-engined Junkers Ju 52 commercial airliner of the

German Lufthansa airline.

Later on BMW produced an originally designed 9-cylinder,

air-cooled radial engine, the BMW 132, which powered, among others, the Ju 52 and the Focke-Wulf Condor. Again, many record flights were undertaken with the BMW 132, four of these units installled in a Focke-Wulf Fw 200 Condor enabling that commercial airliner to establish a flight time of 45 hours over the route

Berlin - New York - Berlin in 1938 and 42 hours from

Berlin to Tokyo that same year.

The development of a twin-row, 14-cylinder radial followed: the BMW 801, with production beginning in 1939. It was the world's first aero engine having a so-called command regulator which automatically adjusted supercharger pressure, fuel mixture, ignition advance and supercharger gear-change. This engine's maximum power eventually amounted to 2400 bhp and, fitted with an

exhaust -driven supercharger, developed 1,800 bhp at an altitude of 12,000 metres. The highpoint of BMW's aero

piston engines was attained by a 28-cylinder unit consisting of two 14-cylinder radials coupled together. However, due to the Second World War's end only one

prototype was built and it yielded 3,500 bhp.

During the development of the last

piston engines the realization dawned that the design limits of this type of powerplant were being approached and that the increased demands of the airframe manuufacturers could only be met by following a new path. The way led to the jet engine. BMW therefore undertook the design studies for this new propulsive unit at an early date and in 1938 the first experimental unit, the BMW 109-003 turbojet, was produced. It was an axial-flow engine with an adjustable jet orifice, and was mounted in the

Messerschmitt Me 262, the first production-built jet fighter, which was also the first jet to see actual combat.

The engine was also used to power the Arado Ar 234, a jet bomber. In its final version this unit attained a thrust of 800 kp (Kiloponds) and in its overall concept can still be considered as a modern construction to this date. Furthermore, there were some interesting designs under construction at that time, such as the BMW 109-018 turbojet unit which could attain a thrust of 3,500 kp (Kiloponds) BMW had also developed a turbo-prop engine with two contrating airscrews which produced 7,000 bhp. Also of interest were a regulated-thrust rocket engine and a combination powerplant which consisted of a BMW turbojet coupled to a rocket engine.