Nicholas Monsarrat

The Auto Transmission can be traced back to one of the most unlikely people you would expect - none other than Nicholas ('Cruel Sea') Monsarrat - who developed an automatic gearshift in 1921 at the age of eleven. It was an infinitely variable ratio system with a governor, collar and ratchet. He showed it to his house master who analysed it carefully. He discovered that it would change up but not down. Monsarrat was discouraged from finding the solution in school time and turned to less mechanical pursuits. But where he failed, others succeeded.

The Automatic really started to find favour with motorists, particularly American motorists, after the 2nd World War.

Year after year, manufacturers increased the percentage of automatic models and, by as long ago as 1969, only around 10% of all cars sold in the States were fitted with a manual cog-changer. That 10% was largely made up of imported sports cars, and

Volkswagen Beetles. Things were not so much different here in Australia either. Sales figures for

1970 show that only 32% of Chrysler Valiant's sold that year were fitted with a manual transmission.

Low Power + Automatic = No Power

Automatic transmission systems (or rather the desire for them) were not new. When motor cars evolved to the point that they were comfortable to ride in, there began the search for added refinement and ease of driving. Most prominent of the dreams of early motorists was automation. There were manifold problems to overcome, not the least of which was the inability of early engines to pull their own weight let alone push around an

automobile and have even more power robbed by the fitment of an automatic transmission. Many weird but hardly wonderful systems were tried and abandoned. Belts sliding down cones or jumping from one pulley to another of different size soon proved impractical as faster engine speeds were achieved.

A centrifugal clutch with high and low speed ranges was available on the Sturtevant car from America in 1904. It came and went. Friction drive as employed on the Metz cars before the Great War survived for a number of years. Apart from giving the Metz and infinitely variable set of ratios the friction drive also gave high returns in fuel economy. Unfortunately (because friction drive was a simple and efficient system) it had one distinct drawback. The linings employed on the friction wheel could not stand slippage and soon wore flat-spots which gave the car an interesting kangaroo motion accompanied by severe thuds and bangs.

The Owen Magnetic

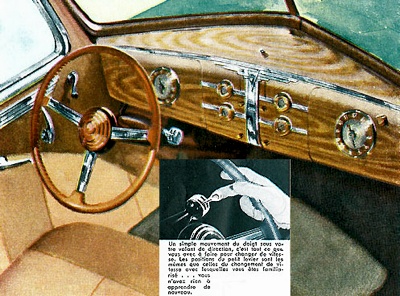

Electrically based transmissions seemed to offer distinct possibilities. The Owen Magnetic, once again from America, was one of the first cars to use a non-positive connection between engine and driving wheels with the substitution of a motor generator for clutch and gearbox. The stator, or field windings, was mounted on the engine in place of the flywheel and the armature was mounted on the drive-shaft. Rotation of the engine and field coils created a magnetic attraction on the armature and when the coils were energized by the control switch on the

steering column the drive shaft turned.

This system, like friction drive, offered an infinite number of speeds and had the added advantage of being a brake or reverse gear simply by reversal of current in the windings. The Owen Magnetic operated smoothly but its electric transmission was heavy, complex and expensive - three good reasons for its extinction. But, with certain modifications, electric gearchanging was offered on a number of cars right up to the early fifties when the last examples of the Cotal system, as employed on

Delage and

Delahaye, disappeared. The Cotal was an epicyclic box using a number of flat discs made from magnetic iron to control the various elements of the mechanism.

The Hudson Electric Hand

The

gear lever operated a simple switch controlling current from the car

battery to the electromagnets. Four speeds were provided and except for depressing the clutch for the initial selection of first gear, driving was simply a matter of shifting the lever from gate to gate. There was a certain amount of strain on the mechanism and gearbox collapse was not unknown.

Hudson also offered an electric shift. It was combined with vacuum operation and is best described by its title, 'Electric Hand'. A complicated mass of wiring, levers and vacuum cylinders bolted to the normal Hudson gearbox were actuated by a miniature

gear lever on the

steering column. Requiring constant attention and maintenance, the 'Electric Hand', had one good feature - it could be readily replaced by the normal Hudson gearbox top and lever.

The best thing about the Hudson Electric Hand was that it was relatively easy to switch it to a traditional gearbox when you finally gave up with the reliability issues.

The best thing about the Hudson Electric Hand was that it was relatively easy to switch it to a traditional gearbox when you finally gave up with the reliability issues.

Popular in the UK, Pre=Selector gearboxes proved almost reliable enough for race track use.

Popular in the UK, Pre=Selector gearboxes proved almost reliable enough for race track use.

|

Dr. Fottinger and the Hydraulic Torque Converter

Another system which proved successful but was not widely known was that employed by the Reo company. Centrifugally activated governor weights and lockable multiple discs took over at speeds above fourteen mph leaving the depression of the clutch for selection of 'drive' as the only movement required of the driver. But full automation was still not available. Sliding wheels and electricity then, were not the answer. It was left to Archimedes and his ancient formulae to provide the basis for successful automatic transmission. The first interpretation of ancient theories in modern terms came with the invention of the fluid coupling and hydraulic torque converter by Dr. Fottinger of the Vulcan-Werke shipbuilding concern in Hamburg in 1905.

The Fottinger hydraulic torque converter was eventually developed in 1912 gave a speed reduction of 5 to 1 and efficiency of about 88%. The British took the hydraulic coupling (in the form of the Daimler and Lanchester fluid flywheel) to their hearts and left the torque converter to the Americans. The good use they made of it is self evident. Early attempts at utilizing hydraulic pressure to transfer engine power were usually spectacularly unsuccessful. Unable to hold the huge pressures generated, the casings in these early experimental cars would blow apart in the messiest possible way. It was only really after WW2 that both hydraulic pressures and the cost of manufacture which inhibited the first systems came down to an affordable price.

The Hydra-Matic

In 1939 Oldsmobiie introduced the Hydra-Matic transmission which was to know such varied application. Rolls-Royce manufactured it under licence and at the other end of the scale Hydra-Matic eased the work load on Aussie Holden drivers. The Hydra-Matic, as finally developed, provided the total automation which had eluded inventors for so many years. Its built-in control system combined balanced hydraulic pressures dependent on car speed, engine speed and the demands of the driver expressed through the accelerator pedal.

The control system was tremendously complex, weight was excessive and power losses were considerable. However these difficulties were overcome and Hydra-Matic became a national institution in the American car. In the same year as the release of Hydra-Matic, Chrysler introduced a transmission called Vacamatic. This consited of a multi-vane coupling with a central reservoir, a friction clutch and a more or less conventional four-speed synchromesh gearbox. A vacuum and electric control unit gave automatic gear changing. Other car makers in America and overseas followed General Motors with their torque converter automatic transmission and it was this type which (in varying guises) that was fitted to the majority of automatic vehicles throughout the last century.

The Daimler Fluidrive

In England, the fluid-fiy wheel claimed the attention of engineers to the exclusion of completely automatic systems. Fitted to the Daimler in 1930 and called the Fluidrive, it offered wonderfully smooth operation, but not full automation. The two main parts of the fluid-flywheel were the runner connected with the gearbox and the casing bolted to the engine crankshaft. Transmission of power depended upon oil circulation between the pockets on the runner and casing. The behaviour of the fluid-flywheel clutch was governed almost entirely by engine speed and not load.

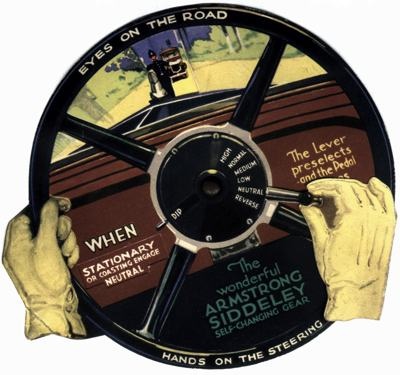

The Wilson Pre-Selector

The Wilson pre-selector gearbox also gained favor and relatively wide usage in England. It gave a certain amount of automation in that the driver selected the required gear and engaged it at will by thumping the clutch pedal. Preselector gearboxes were fitted to racing cars and proved efficient and durable. Daimler combined the Wilson preselector gearbox with their fluid-flywheel on a number of models. Weight was a handicap, and some people found them difficult to use (including

Tazio Nuvolari in the MG Magnette). The early fifties saw the last serious usage of the preselector set up.

The Hobbs automatic transmission had been in the development stage in England for many years and in 1950 was employed on commercial vehicles. It consisted basically of three epicyclic trains controlled by five friction discs. The drive was automatically connected when the engine speed fell below a preset figure. Although no clutch pedal was needed, gearchanging was not automatic but responded to the movement of the

gear lever.

Borg-Warner

The Borg-Warner company in England developed an automatic transmission system similar in basic design to the Hydra-Matic. Available in two variations, type 35 for cars with an engine capacity between 1.5 and 3 litres and the type DG for the larger machines such as

Aston Martin,

Jaguar and

Rover 3 litre. Borg-Warner's unit comprised a three element torque converter and planetary gearbox. The DG gained favor in the early fifties, notably fitted to the Jaguar Mk VII. The

Rootes Group began using the type 35 on their mid-range cars in the early 1960s.

Possibly the greatest contemporary advance in the automatic field was the development by

BMC of a completely new unit for their

Mini De Luxe. The system was controlled by a selector lever and gate mounted centrally on the floor in a similar position to the gear change on the manual Mini De Luxe. The selector could engage seven positions - reverse, neutral and drive for normal automatic operations, and first, second, third and fourth gears for manual operation or if over-ride of automatic drive was required. The system can be used in three different ways.

The first was as a fully automatic four-speed transmission from rest to maximum speed with the gears changing automatically. A 'kickdown' on the accelerator pedal immediately produced an appropriate gear for maximum acceleration. The 2nd was with complete manual control of all four gears by use of the selector lever. This allowed the driver to make rapid changes at whatever speed they wanteds. It also allowed for full engine braking in 2nd, 3rd, or 4th gears when descending hills. 3. It is possible to engage any gear and use the very smooth characteristics of the torque converter which coupled the engine to the automatic transmission to start from rest.

The successful adaptation of automatic transmission to small engines had been the great stumbling block of manufacturers for many years. With the successful performance of such cars as the Toyota 700 and Corolla from Japan, the Mini from England and the Dutch

Daf (with belts and pulleys) the joys of automatic transmission were no longer restricted to the buyer able to purchase larger engined and larger priced vehicles. Looking back on the early automatic systems today, it is obvious that many had their faults. The damper on the flywheel in Hydra-Matic units tended to chew out the splines. Up to the

1965 XP Falcon there was a problem with hardened seals preventing the engagement of top gear. Due to the use of debatable quality oil, pre-VC model

Valiants often suffered from a delay in shifting as varnish from the oil gradually gummed up the works.

Today the difference in fuel consumption between auto and manual cars is slight, if any. But 20+ years ago fuel consumption was nearly always higher on automatic models and this was a point against them.